Abstract

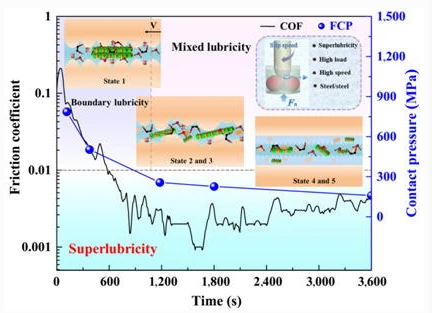

Macroscale superlubricity is a prospective strategy in modern tribology to dramatically reduce friction and wear of mechanical equipment; however, it is mainly studied for point-to-surface contact or special friction pairs in experiments. In this study, a robust macroscale superlubricity for point-to-point contact on a steel interface was achieved for the first time by using hydroxylated modified boron nitride nanosheets with proton-type ionic liquids (ILs) as additives in ethylene glycol aqueous (EG(aq)). The detailed superlubricity process and mechanism were revealed by theoretical calculations and segmented experiments. The results indicate that hydration originating from hydrated ions can significantly reduce the shear stress of EG(aq), which plays an essential role in achieving superlubricity. Moreover, the IL induces a tribochemical reaction to form a friction-protective film. Hydroxylated boron nitride nanosheets (HO-BNNs) function as a polishing and self-repairing agent to disperse the contact stress between friction pairs. Superlubricity involves the change in lubrication state from boundary lubrication to mixed lubrication. This finding can remarkably extend the application of superlubricity for point-to-point contact on steel surfaces for engineering applications.

Keywords Plus:FRICTION COEFFICIENTSULTRALOW FRICTIONLUBRICATIONGRAPHENEWATERLAYERWEAR

Published in FRICTION;10.1007/s40544-021-0545-x,DEC 2021