Abstract

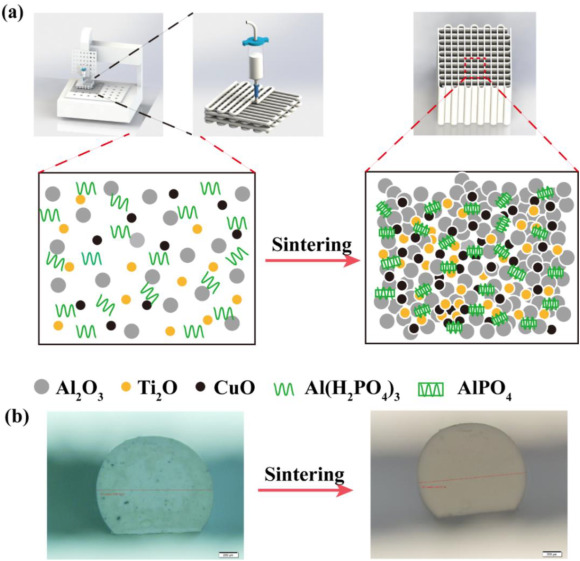

Three-dimensional (3D) printing of ceramics has attracted increasing attention in various fields. However, the pyrolysis of organic components used for binding or polymerization in 3D printing commonly causes a large shrinkage (up to 30 %-40 %), high porosity, and cracking or deformation, severely limiting practical applications. In this study, 3D printing of Al2O3 ceramic architectures with ultra-low shrinkage is realized by introducing inorganic binder aluminum dihydrogen phosphate (Al(H2PO4)(3), AP) as a ceramic precursor. Compared to organic binders, the inorganic AP binder can undergo crystallization conversion, which reduces mass loss during sintering at high temperatures, resulting in low shrinkage. Moreover, AP can be used as a rheological modifier to regulate the printability of the ceramic ink for direct ink writing of Al2O3 ceramic architectures, such as wood piled scaffolds, honeycomb structures, and tubes with high fidelity. The resultant Al2O3 structural ceramics sintered at 1250 degrees C exhibit good mechanical performance and structural integrity. Most importantly, the linear shrinkage of the printed ceramics is less than 5 %, which is several times lower than that of ceramics with organic binders. This study provides a viable strategy for fabricating high-performance ceramic architectures with good dimensional fidelity for practical applications.

Keywords Plus:3D PRINTING TECHNOLOGYBINDERSTRENGTHTEMPERATURESCAFFOLDSCARBIDEPARTSZRO2

Published in CERAMICS INTERNATIONAL,Volume 48;10.1016/j.ceramint.2021.09.168,JAN 1 2022