Abstract

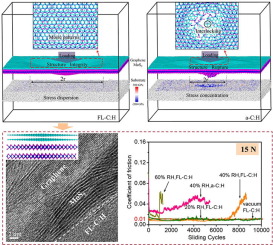

Superlubricity from two dimensional (2D) materials has aroused increasing interest in recent years; however, it can only be achieved below millinewton loads under ambient condition. How to obtain high load-bearing and ambient robust superlubricity remains a challenge but is highly desirable. Here, we use the deformation of highly elastic fullerene-like hydrogenated carbon (FL-C:H) substrate on a large area, to disperse high contact pressure applied on graphene/MoS2 heterojunctions and avoid structure destruction caused by stress concentration. The contact pressure diffusion ensures the structural integrity of 2D materials and promotes their heterointerfacial contact, resulting in high load-bearing superlubricity. Moreover, the maintenance of structural integrity, combined with the preparation of graphene with few defects by using a vacuum ball-shearing exfoliated graphene (BSEG) technique, remarkably weakens environmental chemical interaction to reach ambient robust super lubricity. The BSEG/MoS2/FL-C:H system achieves macroscale superlubricity under vacuum (0.009) and ambient conditions (0.007 at 20% RH, 0.009 at 40% RH) and at engineering load of 15 N. The applied load is far higher than 35 mN that is the known largest values. Atomistic simulations reveal the overall link between contact stress dispersion and experimental observations. This work reveals a novel principle of achieving high load-bearing and ambient robust superlubricity based on contact stress dispersion, and helps to bridge structural superlubricity to practical applications, potentially dramatically reducing energy dissipation.

Keywords Plus:GRAPHENEFRICTION

Published in CHEMICAL ENGINEERING JOURNAL,Volume431,10.1016/j.cej.2021.133548,MAR 1 2022