Abstract

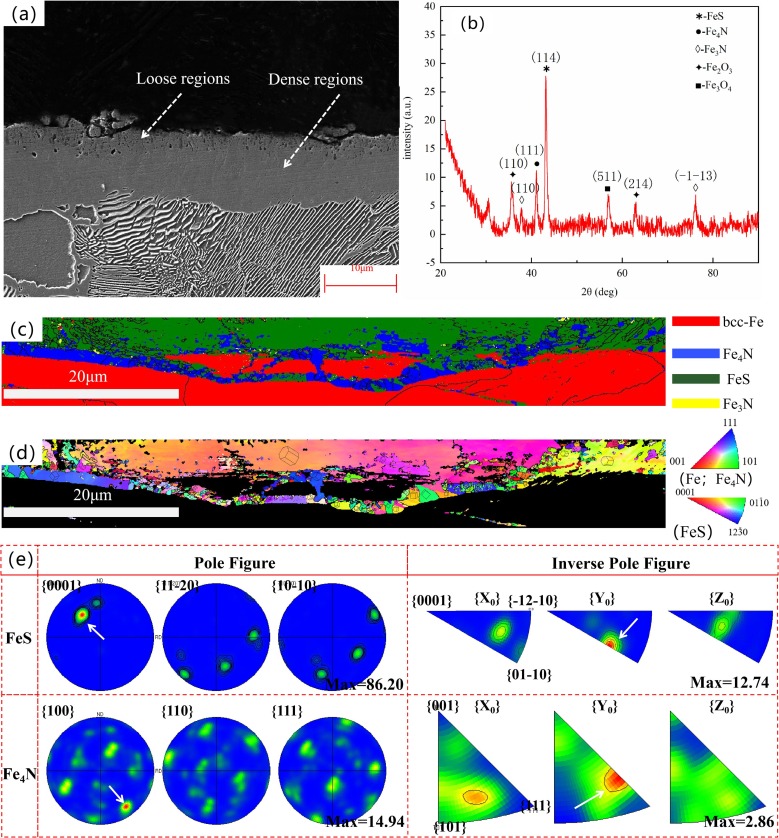

A thermochemical sulfonitriding process was performed on 42CrMo steel parts through immersion in a molten salt bath. A compound layer consisting of FeS and FeN was present on the 42CrMo steel surface with a layered structure. The steel with the sulfonitrided layer was 2.17 times harder than the 42CrMo steel, and exhibited a substantial improvement in wear inhibition and friction reduction over a wide range of temperature. This demonstrates an equivalent tribological capability with the high-sulfur steel. In particular, the modified 42CrMo steel exhibited higher corrosion resistance than the 42CrMo steel and high-sulfur steel during the neutral-salt spray accelerated test. These preliminary results suggest that the formation of the thermodiffusion layer can solve an array of issues associated with material loss and safety incidents caused by wear and corrosion.

Published in MATERIALS LETTERS,Volume318;10.1016/j.matlet.2022.132172,JUL 1 2022