Abstract

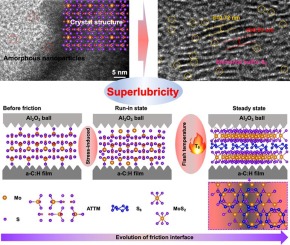

In the past decade, significant breakthroughs have been made in uncovering the superlubricity mechanism and in developing superlubric materials. However, most works have concentrated on nanoscale two-dimensional (2D) nanomaterials, which are still a challenge for industrial scale-up. Meanwhile, although some hydrogenated amorphous carbon (a-C:H) films show superlubricty, how to break through the components and restrict the nanostructure is in the struggle because commercial a-C:H films with a friction coefficient beyond 0.05 are far from superlubricity (<0.01). To address these problems, we used ammonium tetrathiomolybdate (ATTM) as an additive to synergize with an a-C:H film to realize superlubricity on a 9Cr18Mo steel surface in argon and nitrogen atmospheres. Thanks to the flash heating and shear force during friction, the ATTM can be decovoluted into molybdenum disulfide (MoS2) and sulfur monomer (S8), which are naturally irrational in lattice parameters, i.e., incommensurate contact between MoS2 and S8 is the key to superlubricity. A comparative study shows that a-C:H here not only helps to anchor ATTM to inhibit easy slip at the beginning but also plays an anti-wear role for 9Cr18Mo steel in superlubricious states. Our work opens a new notion to scale up structure superlubricity for industrial application.

Keywords Plus:DIAMOND-LIKE CARBONMACROSCALE SUPERLUBRICITYTRIBOLOGICAL PROPERTIESGRAPHENE OXIDEDLC FILMSFRICTIONWEARCAPACITYSULFURMOS2

Published in APPLIED SURFACE SCIENCE,Volume597;10.1016/j.apsusc.2022.153675,SEP 30 2022