Abstract

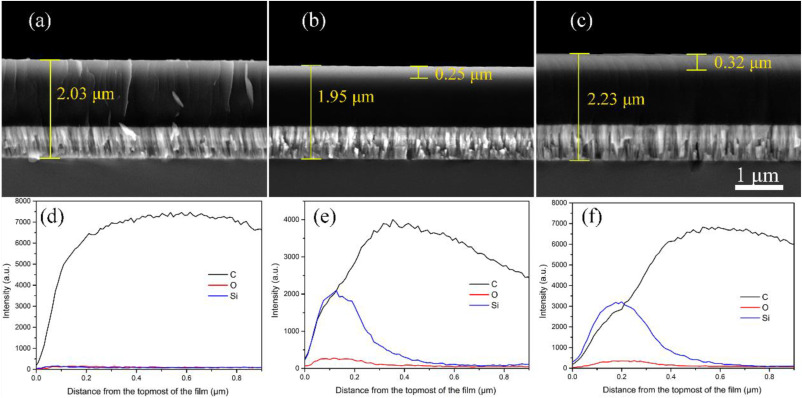

During the deposition of a-C:H film, defects (pinholes or discontinuities) caused by excessive stress will inevitably appear, which will reduce the corrosion resistance of the a-C:H film. In this study, top a-C:H:Si:O layers (thickness of approximately 0.3 mu m) on the surface of a-C:H films were deposited on a large scale by PACVD technology using acetylene (C2H2) and/or hexamethyldisiloxane (HMDSO) as reactants, to improve the corrosion resistance of a-C:H films while ensuring the appropriate overall hardness of the films. The corrosion behaviors of the films were studied by electrochemical impedance spectroscopy (EIS) and Tafel polarization. We found that the a-C:H/a-C:H:Si:O films possess a lower electrolyte penetration rate due to their stronger capacitance characteristics. In addition, the corrosion current density of the a-C:H/a-C:H:Si:O films (10-10 A cm-2) were reduced by 2 orders of magnitude compared to the a-C:H film (10-8 A cm-2), and by 3 orders of magnitude compared to 316 stainless steel (10-7 A cm-2). The impedance results obtained by EIS were simulated using appropriate equivalent circuits, and the corresponding electrical parameters were used to further verify the electrochemical protection behavior of the top a-C:H:Si:O layer.

Keywords Plus:MECHANICAL-PROPERTIESSTAINLESS-STEELCARBON-FILMSATOMIC LAYERTHIN-FILMSPERFORMANCEBEHAVIORSIDEPOSITIONCOATINGS

Published in CERAMICS INTERNATIONAL,Volume48;10.1016/j.ceramint.2022.04.113,AUG 1 2022