Abstract

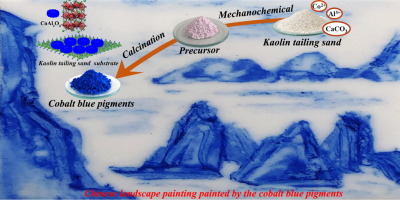

To reduce the wastes discharging and production cost for preparation of cobalt blue pigments via common liquid-phase methods, the low-cost and high-chroma cobalt blue composite pigments are fabricated via CaCO3-assisted mechanochemical route followed by an annealing process based on the discarded kaolin tailing sand (KTS) from the mineral processing. The preparation conditions, formation and coloring mechanisms of composite pigments are studied systematically. The optimal color performance (L* = 40.54, a* = 4.12, b* = -55.22) is obtained after optimizing the preparation conditions. The results indicate that CaCO3 acts as a mild precipitant with the assistance of mechanochemical effects to form the precursor. Furthermore, incorporation of KTS improves the color lightness and blueness of cobalt blue pigments due to the reflection of KTS toward light and well dispersion of CoAl2O4 on KTS surface. Compared with the commercial cobalt blue pigments, the oil absorption and hiding power of composite pigments are high while the relative tinting strength slightly reduces owing to the differences in their size and CoAl2O4 content, but the composite pigments may be more popular due to the low production cost and excellent color performance. Moreover, the as-prepared composite pigments present excellent acid-resistance and coloring performance as a ceramic pigment.(c) 2022 The Korean Society of Industrial and Engineering Chemistry. Published by Elsevier B.V. All rightsreserved.

Keywords Plus:PHYSICAL-PROPERTIESOPTICAL-PROPERTIESION BATTERIESCOAL2O4PARTICLESTEMPERATURESPINELFABRICATIONDEPOSITIONSTABILITY

Published in JOURNAL OF INDUSTRIAL AND ENGINEERING CHEMISTRY,Volume112;10.1016/j.jiec.2022.05.042,UG 25 2022