Abstract

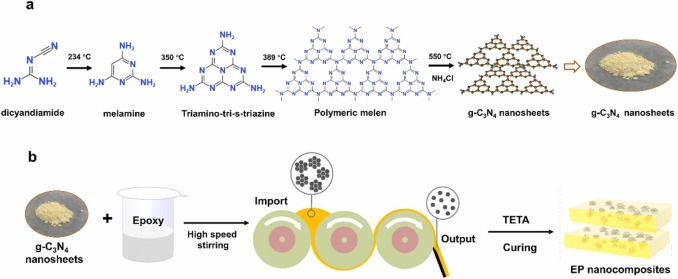

It is of great interest to realize controllable tribo-designs of a large variety of motion components operating under starved lubrication conditions. In this work, g-C3N4 nanosheets were prepared and uniformly dispersed into pure epoxy (EP) matrix. Especially for sliding with only 5 mu L oil supply. In comparison to neat EP, friction coefficient and wear rate are reduced by up to 27% and 83% with addition of only 1% g-C3N4. Research illustrates a small amount of two-dimensional g-C3N4 nanosheets promote the growth of robust tribofilm on oil starved interface. The carbonous top layer of tribofilm benefits the boundary lubrication effect of the sliding pair, whereas the beneath layer confers a high load-bearing ability to tribofilm. It is anticipated that this work will pave a route for designing new polymer nanocomposites serving under oil starved conditions.

Keywords Plus:CARBON NITRIDE NANOSHEETSELASTOHYDRODYNAMIC LUBRICATIONBEHAVIORWEARFRICTIONCOMPOSITES

Published in TRIBOLOGY INTERNATIONAL,Volume174;10.1016/j.triboint.2022.107762,OCT 2022