Abstract

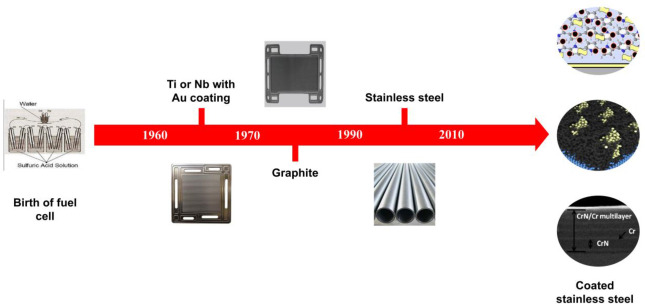

Proton exchange membrane fuel cell has attracted much attention in recent years due to their advantages of environmental protection and high resource utilization, which is important for improving the global environment. Bipolar plates are the important components of fuel cell, which accounts for most of the weight and high cost. Compared with graphite bipolar plates, metal bipolar plates are easier to machining and have lower cost because of its good mechanical properties. However, in the acidic environment of proton exchange membrane fuel cell operation, metal bipolar plates are prone to corrosion, which leads to lower output efficiency of fuel cell and seriously affected the application. Applying a protective coating to the metal bipolar plates is an effective way to improve its corrosion resistance. This paper mainly introduces the research progress of several anti-corrosion coatings for metal bipolar plates in recent years, and summarizes the challenges and future requirements of metal bipolar plates.(c) 2022 Hydrogen Energy Publications LLC.

Keywords Plus:316L STAINLESS-STEELINTERFACIAL CONTACT RESISTANCEAMORPHOUS-CARBON FILMSSIMULATED CATHODIC ENVIRONMENTCORROSION BEHAVIORELECTRICAL-PROPERTIESELECTROCHEMICAL-BEHAVIORCOATED 304-STAINLESS-STEELAISI 304-STAINLESS-STEELSURFACE CONDUCTIVITY

Published in INTERNATIONAL JOURNAL OF HYDROGEN ENERGY,Volume47;10.1016/j.ijhydene.2022.05.078,JUN 29 2022