Abstract

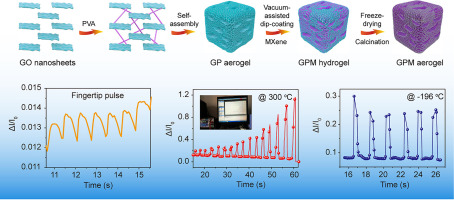

With the broader application of intelligent sensors in various complex conditions, sensing materials with better mechanical and conductive properties as well as higher temperature adaptability are required. For this purpose, a GO/PVA/MXene (GPM) composite aerogel was designed and prepared via a two-step strategy, including self -assembly and vacuum-assisted dip-coating processes. The as-prepared GPM has a unique structure composed of hierarchical GO network skeleton and MXene coating, endowing it with high Young's modulus (11.2 kPa) and compressibility (90%). Demonstrated with the finite element (FE) simulation, the elasticity and toughness of the GPM are originated from the hierarchical microstructure and the improved thickness of shells. Besides, the GPM exhibits a long-term durability of 5,000 compression cycles at 50% strain, a high sensitivity of 1.744 kPa(-1), and a rapid response time of 4.5 ms. Further application examples reveal that the pressure sensor based on GPM has superior physiological signal capture capability, realizing fingertip pulse and temporal artery detections. Moreover, the GPM aerogel possesses high thermal insulation efficiency, resulting in good temperature adapt-ability in harsh environments from-196 ?C to 300 ?C. The sensitive pressure sensors should have the potential application in many fields of intelligent factories, complex militaries, and space discoveries.

Keywords Plus:GRAPHENE AEROGELSCARBONFOAMSOXIDE

Published in carbon,Volume200;10.1016/j.carbon.2022.08.002,NOV 5 2022