Abstract

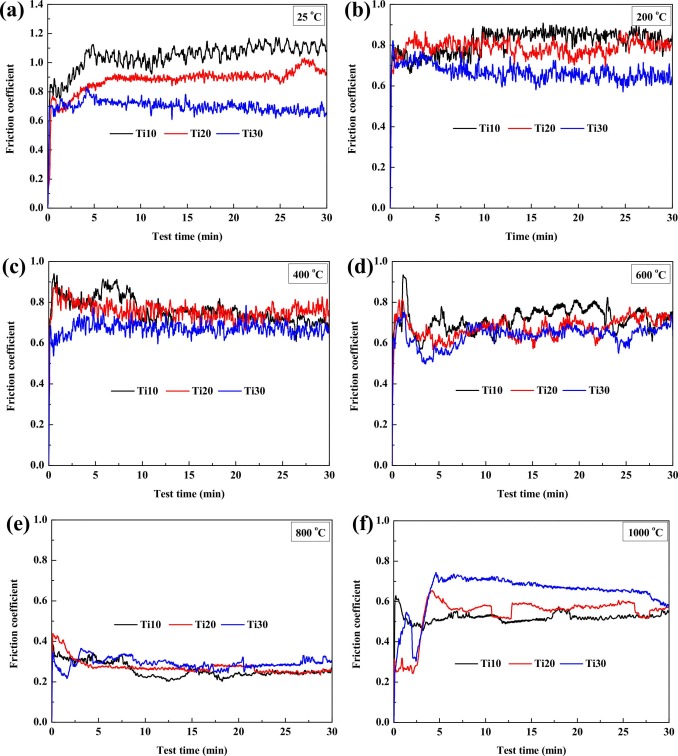

The search for Mo-Si-B based alloys exhibit excellent high-temperature wear resistance is highly demanding for their structural applications. For this target, the Mo-Si-B-xTi (x = 10, 20 and 30 wt%) alloys were fabricated and their dry sliding tribological properties at 25-1000 degrees C in air were systemically investigated. It indicates that the tribological properties of the MoSiBTi alloys are greatly determined by the test temperature and Ti content that correlates to oxidization process and oxidation products. Compared with other alloys, the Ti30 alloy shows an excellent wear resistance at 600-1000 degrees C due to the formation of dense tribo-oxides layer and improved oxidation resistance. Meantime, the friction coefficient at 800 degrees C is as low as 0.31 because of the formed self-lubricating tribolayer.

Keywords Plus:OXIDATION BEHAVIORCREEP

Published in TRIBOLOGY INTERNATIONAL,Volume177;10.1016/j.triboint.2022.107897,JAN 2023