Abstract

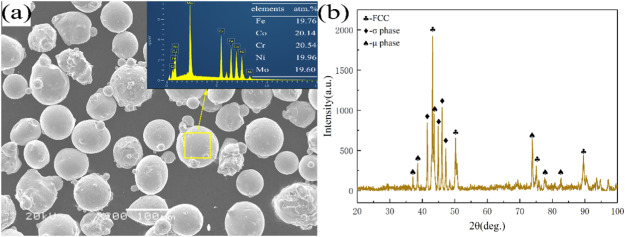

High entropy alloys (HEAs) are expected to design novel materials for elevated temperature applications through controlling phase composition and microstructure. In this work, a CoCrFeNiMo HEA coating with excellent high temperature wear resistance was prepared by laser cladding technology. The content of precipitates decreased with the increase of laser power and the microstructure of matrix changed from reticular to dendritic structure due to the effect of molten pool flow and substrate dilution. With the decrease of the precipitates size and the formation of eutectic structure, the oxide glaze layer formed on the coating shows excellent antifriction per-formance. Additionally, the smooth and dense oxide glaze layer can significantly decrease the wear rate of the HEA coating in the subsequent friction process.

Keywords Plus:SIGMA-PHASE PRECIPITATIONMECHANICAL-PROPERTIESCOCRFEMNNINANOINDENTATIONBEHAVIORGLASSCR

Published in SURFACE & COATINGS TECHNOLOGY,Volume449;10.1016/j.surfcoat.2022.128978,NOV 15 2022