Abstract

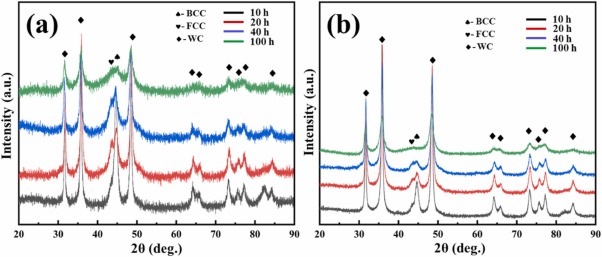

Mechanical alloying is the most popular processing method for preventing nanoparticle agglomeration in metal matrix nanocomposites and is one of the primary methods for preparing high-entropy alloy (HEA) powders. In this study, HEA matrix nanocomposite powders with a diffuse distribution of tungsten carbide are prepared by adding WC during the preparation of FeCoCrNiAl HEA through high-energy ball milling by extending the ball-milling time. After 10 h of ball milling, a body-centered cubic (BCC)-phase HEA is obtained, and WC particles are observed to have adhered to the surface of the HEA matrix powder. With a further increase in the ball-milling time, the WC particles continuously fracture and adhere to the matrix powder. During repeated plastic deformation, fracture, and cold welding of the HEA powder, the BCC phase gradually transforms into a face-centered cubic (FCC) phase, and the WC microfine powder is gradually and uniformly dispersed in the HEA matrix. The dynamic process between repeated cold welding and fracture ensures a stable powder size and inhibits the agglomeration of WC particles. Simultaneously, the intrinsic properties of the HEA lead to a gradual spheroidization of the composite powder. A final FCC and BCC biphasic HEA-matrix WC nanocomposite spherical powder is produced.(c) 2022 Elsevier B.V. All rights reserved.

Keywords Plus:STRENGTHTRANSFORMATIONCOMPOSITESDUCTILITYNANO

Published in JOURNAL OF ALLOYS AND COMPOUNDS,Volume938;10.1016/j.jallcom.2022.168518,MAR 25 2023