Abstract

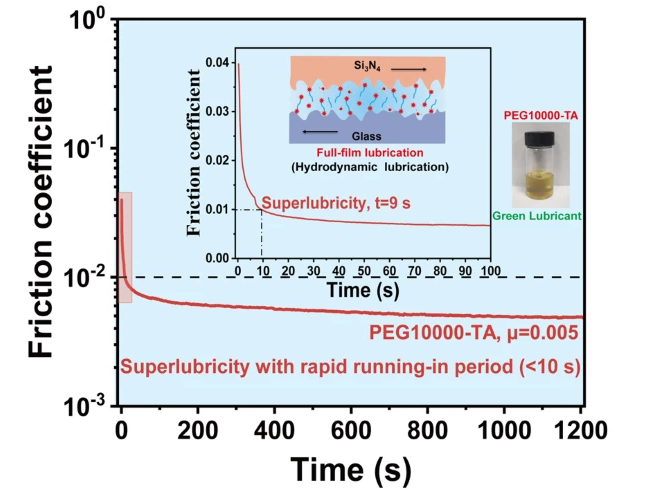

Superlubricating materials can greatly reduce the energy consumed and economic losses by unnecessary friction. However, a long pre-running-in period is indispensable for achieving superlubricity; this leads to severe wear on the surface of friction pairs and has become one of the important factors in the wear of superlubricating materials. In this study, a polyethylene glycol-tannic acid complex green liquid lubricant (PEG10000-TA) was designed to achieve macroscale superlubricity with an ultrashort running-in period of 9 s under a contact pressure of up to 410 MPa, and the wear rate was only 1.19 x 10(-8) mm(3)center dot N-1 center dot m(-1). This is the shortest running-in time required to achieve superlubricity in Si3N4/glass (SiO2). The results show that the strong hydrogen bonds between PEG and TA molecules can significantly reduce the time required for the tribochemical reaction, allowing the lubricating material to reach the state of superlubrication rapidly. Furthermore, the strong hydrogen bond can share a large load while fixing free water molecules in the contact zone to reduce shear interaction. These findings will help advance the use of liquid superlubricity technology in industrial and biomedical.

Keywords Plus:PHOSPHORIC-ACIDHYDRODYNAMIC LUBRICATIONSILICON-NITRIDESLIDING SPEEDFRICTIONWATERMIXTURESSURFACESBEHAVIORSI3N4

Published in FRICTION,Volume11;10.1007/s40544-022-0660-3,MAY 2023