Abstract

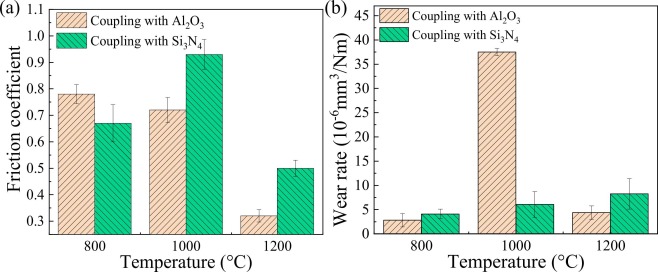

The tribological behaviors of MoAlB ceramic were studied using different counterpart materials under 800-1200 degrees C, and the influences of the counterpart material and temperature are intensively discussed. The results indicate that MoAlB shows outstanding wear resistance (the wear rate is within 10-6 mm3 center dot N- 1 center dot m- 1) under 800-1200 degrees C and excellent lubricating performance at 1200 degrees C (the friction coefficient is as low as 0.3), which is almost the best performance reported for ceramics at high temperature so far. Besides, the counterpart ball with higher hardness always causes higher wear rate of MoAlB. However, the effect of the temperature is closely related to the hardness and the oxidation degree of MoAlB disc. At 800-1000 degrees C, the wear mechanism is mainly the abrasive wear because of the uncompact Al2O3 product. At 1200 degrees C, the low-shear plastic deformation of the nanocrystalline Al2O3 layer and the discontinuous MoO3 film together result in the excellent tribological behaviors of MoAlB.

Keywords Plus:MATRIX COMPOSITESSOLID LUBRICANTSSIALON CERAMICSWEARFRICTIONMICROSTRUCTUREDEPENDENCESTRENGTHAL2O3XPS

Published in TRIBOLOGY INTERNATIONAL,Volume185;10.1016/j.triboint.2023.108522,JUL 2023