Abstract

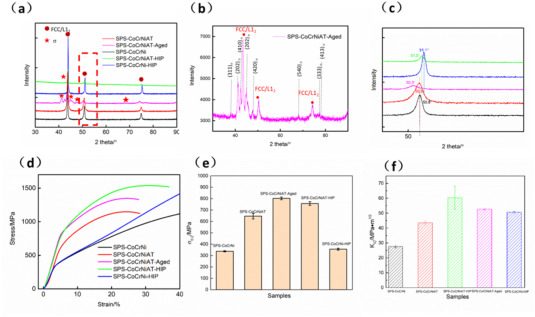

In the present study, hot isostatic pressing (HIP) subjected to high intermediate cooling rate is exploited to seal keyholes and tune the microstructure of equiatomic CoCrNi and (CoCrNi)94Al3Ti3 medium entropy alloys (MEAs) prepared by spark plasma sintering (SPS). For equiatomic CoCrNi, fracture toughness (KIC) is significantly increased but the yield strength (50.2) is almost constant when the relative density is increased from 98.9% to 99.7% by HIP. By contrast, 50.2 and KIC of (CoCrNi)94Al3Ti3 are considerably advanced by 27.3% and 38.6%, respectively. Meanwhile, the change of grain size introduced by HIP treatment is very inconspicuous in present study. Obvious plastic deformation traces are observed near the crack in the samples subjected to HIP treatment. Systematic microstructure observations indicate that the nano-precipitates and the concurrent of the long split 9R structure and nanotwins in (CoCrNi)94Al3Ti3 formed during HIP treatment are responsible for the enhance-ment of 50.2. The formation mechanisms of 9R phase in terms of the hierarchical architecture twins and dislo-cations activity are explored. Our findings offer new insights on design and processing of MEAs parts by the powder metallurgy.

Keywords Plus:GRAIN-BOUNDARYMECHANICAL-PROPERTIESPHASEDISLOCATIONSTEELFCC

Published in INTERMETALLICS,Volume159;10.1016/j.intermet.2023.107929,AUG 2023