Abstract

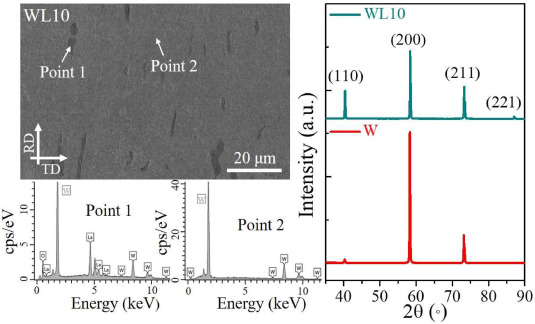

Surface modification, sputtering erosion and deuterium (D) retention were investigated of tungsten (W) and W-1 wt.% La2O3 (WL10) that were exposed to pure D plasma and D plasma with different impurities (He, N2, Ar). After the plasma exposure, the surface of WL10 is covered by blisters with various shapes, and their size and density increase with D fluence. When the fluence was higher than 8.6 x 1024 D m-2, the blister rupturing occurred causing a partially-and/or fully-opened lid features. The phase interface between La2O3 grains and W matrix was served as the nucleation sites for blistering and large-scale crack propagation near the surface. Small blisters were preferentially appeared on the grains with surface orientation of nearly (111) and that originated from the intra-granular crack at depths much closer to the sample surface. Micro-sized pits were formed on the WL10 surface after exposure to high fluence plasma, which was due to a higher sputtering rate of La2O3 grains during plasma exposure. For both materials, seeding He in D plasma can effectively inhibit the blister formation, and most serious blistering occurs with N seeding in D plasma. When exposed to Ar + D plasma, sparse small blisters were visible and most of blisters were ruptured for W, whereas there are some big blisters with long strip shape for WL10. The difference in blistering behavior between W and WL10 was attributed to the differences in microstructure, composition as well as ductility due to the presence of La2O3 phases. The sputtering yields increased slightly with He seeding in D plasma. N2 and Ar seeding in D plasma leaded to a significant increase in sputtering yields. As compared to the W, the WL10 exhibits a better sputtering erosion resistance in terms of the sputtering yield. The D retention in WL10 increases with D fluence and that was equal to or lower than that in W when exposed to the same conditions.(c) 2022 Hydrogen Energy Publications LLC. Published by Elsevier Ltd. All rights reserved.

Keywords Plus:HIGH-FLUXLOW-ENERGYMECHANICAL-PROPERTIESBLISTER FORMATIONTUNGSTENTEMPERATUREDEPENDENCEMICROSTRUCTURERELEASED+

Published in INTERNATIONAL JOURNAL OF HYDROGEN ENERGY,Volume48;10.1016/j.ijhydene.2022.10.107,JAN 19 2023