Abstract

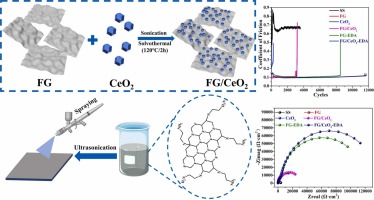

Integrated with friction-reduction, anti-wear, and anticorrosion capacities, a novel fluorinated graphene (FG) composite coating has been developed to address the need for effective protection of metal materials in salty and humid environments. Bound with ethylenediamine (EDA), cerium dioxide (CeO2) nanoparticles decorated FG nanosheets were rapidly in-situ coated on the stainless steel sheet. The experiments revealed that the effective combination of FG, CeO2, and EDA endowed the composite coating with a reduced friction coefficient and an extended lubrication duration. The corrosion performances demonstrated that the composite coating has the highest corrosion potential and the lowest corrosion current, which can be attributable to the physical barrier effect of the FG nanosheets and the chemical corrosion inhibition effect of CeO2 and EDA.

Keywords Plus:EPOXY COMPOSITESCORROSIONNANOCRYSTALLINENANOFILLERCOPPERRAMAN

Published in TRIBOLOGY INTERNATIONAL,Volume187;10.1016/j.triboint.2023.108753,SEP 2023