Abstract

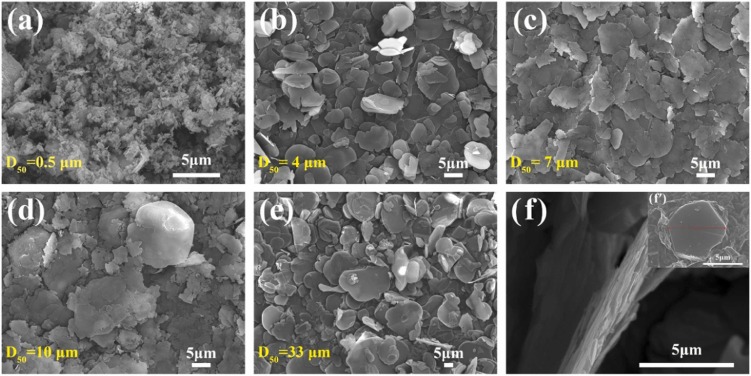

The h-BN platelet size causes significant changes in the efficiency of extruding the lubricant phase from the material interior onto the friction surface, affecting the lubricating films forming and friction coefficient. The highest h-BN release efficiency was achieved when h-BN size in the h-BN/SiO2 composite was 7 & mu;m, causing the lowest friction coefficient (0.20). In addition, the binding force of h-BN and ceramic phases are negatively correlated with their friction coefficients. The high binding force between the two phases contributes to the h-BN release efficiency and the "trapping" of abrasive debris, resulting in the continuous lubricating films and low friction coefficient. The highest binding force between Si3N4 and h-BN, resulting in high h-BN release efficiency and better friction coefficient (0.21).

Keywords Plus:HEXAGONAL BORON-NITRIDEMICROSTRUCTURETEMPERATUREFABRICATIONRESISTANCEFRICTIONLAYERMAS

Published in TRIBOLOGY INTERNATIONAL,Volume187;10.1016/j.triboint.2023.108722,SEP 2023