Abstract

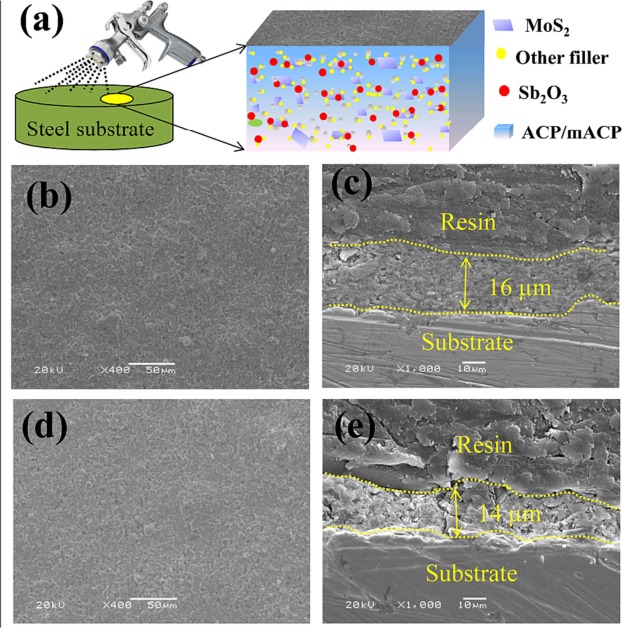

Lubricating materials in harsh space environments demands both good lubricity and excellent properties of the atomic oxygen (AO) irradiation resistance. Herein, an organosilane modified phosphate-based coatings have been fabricated using an air spraying method. The introduction of the organosilane into the phosphate resin at a molecular level extremely improved the flexibility of the coatings which kept the excellent AO resistance performance. It is due to the modified phosphate itself could effectively block diffusion and erosion of the oxygen free radicals during AO irradiation. After AO irradiation, the average coefficient of friction was less than 0.03 and the wear rate reached 10-8 mm3 & BULL;N & BULL;m ? 1 orders of magnitude. More importantly, the wear life was more than 1.5 million cycles. The coatings have great potential to be applied in lubricating protection for mechanical system that long-term serviced in space environment.

Keywords Plus:FILM

Published in MATERIALS LETTERS,Volume351,10.1016/j.matlet.2023.135017;NOV 15 2023