Abstract

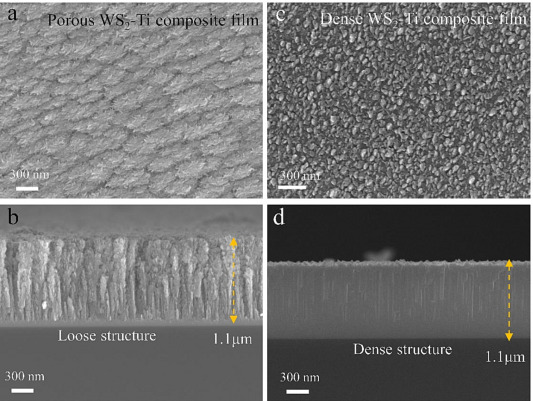

Solid-liquid lubricating technology is a quite effective approach to achieve long life for sliding components in space. Herein, the WS2-Ti films with porous and dense structures were prepared. The tribological performances of WS2-Ti films lubricated in two kinds of space liquid lubricants (P201 and PFPE) were mainly investigated in vacuum compared to the films in dry friction condition. The dense film exhibits the low friction coefficient of 0.02 and ultra-low wear rate of 2.3 x 10-8 mm3 center dot N- 1 center dot m- 1 in the dry friction condition. The dense film/oil coatings also show a very long wear life over 4.5 x 105 r, and their wear rates obviously decrease about 79 % and 67 % under harsh test condition compared to the porous film lubricated in P201 and PFPE, respectively. The related analyses indicate that nonpolar P201 molecule is found to have far better compatibility to WS2-Ti crystal surfaces than polar PFPE molecule. It contributes to forming compact tribolayer consisting of numerous ultrathin nanosheets, significantly extending wear life of the coating. Noteworthily, for the solid-liquid coatings, there is a new find that formation of transfer film firstly underwent amorphization and then occurred recrystallization. This reveals lubricating mechanism of the WS2-Ti/oil coating.

Keywords Plus:TRIBOLOGICAL PROPERTIES,WS2,MICROSTRUCTURE,BEHAVIOR,PRESSURE,FRICTION,CARBON,FILMS,OILS

Published in SURFACE & COATINGS TECHNOLOGY,Volume476,10.1016/j.surfcoat.2023.130245;JAN 30 2024