Abstract

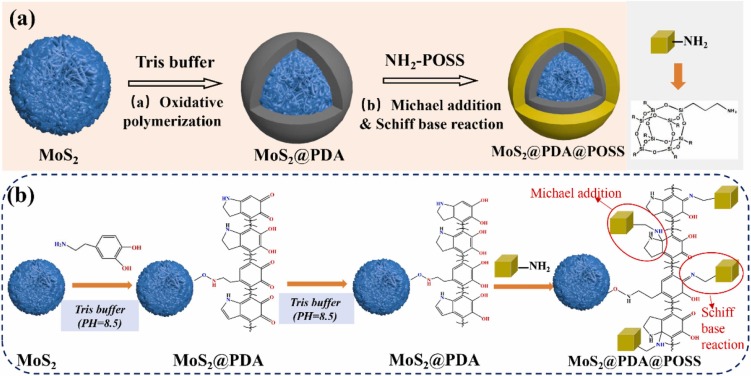

In this work, a humidity-adaptive additive of MoS2@PDA@POSS with core-shell-shell structure was designed and fabricated in the presence of polydopamine (PDA) interlayer. Then the composite coating of MoS2@PDA@POSS/ Epoxy was prepared by introducing this additive into epoxy matrix, and its tribological properties under air and humid environments were subsequently evaluated in detail. Specially, the friction coefficient of MoS2 @PDA@POSS/Epoxy coating under high humid environment remained stable below 0.25, while its volume wear rate reduced by 91.91% compared to MoS2/Epoxy coating, and the humidity-adaptive response mechanism mainly depends on the improved mechanical properties, the alleviating effect on MoS2 oxidation, and the formation of transfer film. This work establishes a promising platform for the design and application of novel highperformance lubricating additives.

Keywords Plus:MOS2,FABRICATION,NANOCOMPOSITES,MORPHOLOGY,EMULSION,FILLERS

Published in TRIBOLOGY INTERNATIONAL,Volume192,10.1016/j.triboint.2024.109301;APR 2024