Abstract

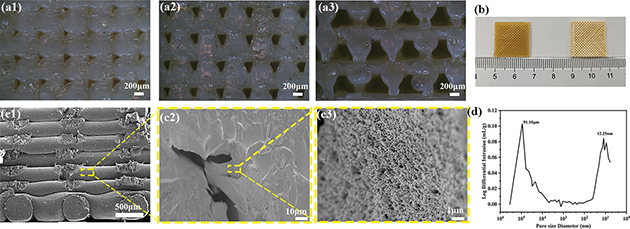

Most mechanical oil leaks and industrial oily wastewater are in complex and harsh environments. Hence, developing a simple and efficient method to store oil or separating oil-water contaminants has become an ongoing challenge. Hierarchically porous polyetheimide (HPPEI) is a promising competitive candidate due to the combination of functional designability, featuring multilayer pores, and the excellent properties of PEI. Herein, HPPEI (micro- and nano-) is developed by fused deposition modeling (FDM) printing, which enables customizable uniform pores, and green and cost-effective supercritical CO2 foaming method. HPPEI exhibits remarkable oil content and oil adsorption rate, attributed to the nanopores functioning as "windows." Nanopores alter the adsorption mode from the "individual adsorption" of PPEI to "interconnected adsorption," accompanied by an increased storage capacity, and enhanced the overall adsorption rate due to strong capillary effect and higher adsorption rate. HPPEI modified with hydrophobic nano fumed silica (HN-SiO2), demonstrates outstanding hydrophobicity and lipophilicity features selective oil adsorption and oil-water separation, and retains excellent hydrophobic even at high temperatures and in acidic and alkaline environments. This material is expected to provide a strategy for energy conservation: selective oil adsorption from oily wastewater in harsh environments and then the oily material is utilized for lubrication areas, avoiding material waste.

Keywords Plus:EFFICIENT

Published in ADVANCED MATERIALS TECHNOLOGIES,10.1002/admt.202301756