Abstract

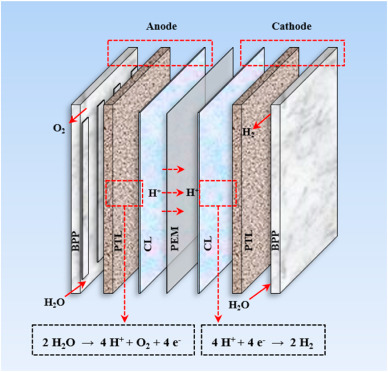

The corrosion resistance, conductivity, and cost of the metallic bipolar plates are the main limitations for the Proton Exchange Membrane Water Electrolysis (PEMWE) commercialization. In the present study, Ta, Nb, and Ti non-precious metallic coatings were deposited by closed-field unbalanced magnetron sputtering to increase the corrosion resistance and conductivity of titanium bipolar plates in PEMWE, respectively. The coating samples suffer from corrosion in a simulated extreme anode operating environment of PEMWE (0.5 M H 2 SO 4 + 5 ppm HF, 80 degrees C, O 2 ). The surface of the Ti coating forms the micropores due to the high dissolution rate in initial formation stage of the passivation film, resulting in a higher current density (1.41 x 10 -6 A cm - 2 ). The hydrolysis reaction of Ta coating causes the adsorption of sulfide ions, thereby affecting the density of the passivation film. Despite the Ta coating exhibiting a favorable current density (4.82 x 10 -7 A cm - 2 ), ICR (463.11 m Omega cm 2 ) is lamentably poor. The surface of Nb coating has been completely covered by Nb 2 O 5 and NbO 2 in the simulated PEMWE environment. The reoxidation process of NbO 2 promotes the rate of passivation film formation and provides excellent conductivity. Therefore, Nb coating exhibits the lowest current density and interfacial contact resistance of 2.23 x 10 -8 A cm -2 and 119.78 m Omega cm 2 , respectively, which is very low compared to the bare titanium bipolar plates.

Keywords Plus:PLANE ELECTRICAL-CONDUCTIVITY,AISI316L STAINLESS-STEEL,ELECTROCHEMICAL PROPERTIES,RESISTANCE,MICROSTRUCTURE,ALLOY

Published in INTERNATIONAL JOURNAL OF HYDROGEN ENERGY,Volume63;10.1016/j.ijhydene.2024.03.242,APR 18 2024