Abstract

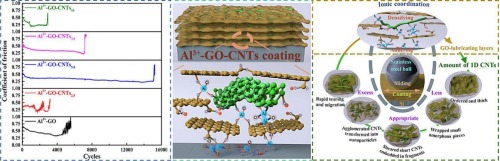

To resolve graphene coating's typical problems in tribological applications, including poor interfacial bonding, agglomeration, and low wear resistance, a dimensionally composited coating based on graphene oxide (GO) and carbon nanotubes (CNTs) was successfully prepared by a feasible metal-ion diffusion-directed assembly method. Experiments showed that the Al 3 + diffusion-directed assembly method could significantly increase the coating interfacial binding strength, elasticity modulus, and hardness. In addition, the synergistic lubrication of GO and CNTs during friction enabled the Al 3 + -GO-CNTs 5 . 0 coating to sustain a longer operation duration of 12,900 cycles. This study refers to inducing coordination with metal ions in various valence states and compositing carbon-based nanomaterials in different dimensions, which provides a feasible way to improve the lubricating coating's mechanical and tribological performances.

Keywords Plus:WALLED CARBON NANOTUBES,REDUCED GRAPHENE OXIDE,FRICTION BEHAVIOR,GRAPHITE,WEAR

Published in SURFACE & COATINGS TECHNOLOGY,Volume 484;10.1016/j.surfcoat.2024.130870,MAY 30 2024