Abstract

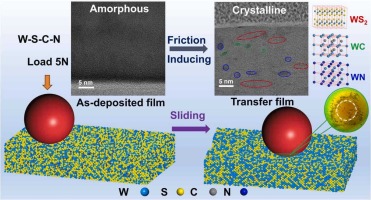

Amorphous W-S-C-N lubricating films were prepared by sputtering two WS2 targets and an additional WC target in Ar&N2 atmosphere. The W-S-C-N film demonstrated a notably stable low coefficient of friction (COF) of approximately 0.01, as well as a wear rate of 1.50 x 10-7 mm3/Nm over extended sliding cycles. These characteristics indicated superior tribological properties compared to the deposited WS2, W-S-C, and W-S-N films. The formation of the friction-induced well-crystallized WS2 transfer film with its (002) basal plane parallel to the sliding surface of the counterpart ball contributed to the low friction of the W-S-C-N film. Furthermore, the embedded amorphous and nanocrystalline WC phase within the crystallized WS2-based transfer film further enhanced the stability and durability of the transfer film.

Keywords Plus:NANOCOMPOSITE COATINGS,BEHAVIOR

Published in TRIBOLOGY INTERNATIONAL,Volume 198;10.1016/j.triboint.2024.109922,OCT 2024