Abstract

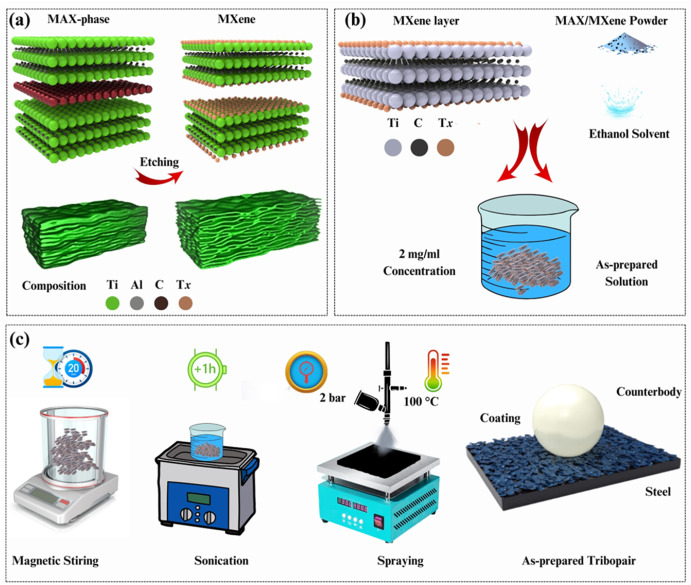

Due to the long-standing use of MAX phase materials since the 1960s and the emergence of MXenes in 2011, both are celebrated for their extraordinary mechano-tribological properties, including layered structures, high mechanical strength, and thermal conductivity. Nevertheless, there remains a crucial research gap in comprehensively comparing their tribological performance under solid lubrication, underscoring the need for an in-depth investigation. To close this research gap, we deposited MAX phase and MXene coatings by spray-coating on stainless-steel substrates. Subsequently, we evaluated their tribological properties, deciphered the underlying mechanisms using linear-reciprocating tribometry and high-resolution material characterizations. Our results demonstrated that the MXene coatings surpass the MAX phase coating in friction reduction by 81.82 %. In terms of wear depth, MXene coating has shown a notably reduced depth compared to both the reference steel sample and the MAX phase coating. Advanced tribochemical analysis indicates that MXenes' superior tribological performance is endorsed by their ability to form a thick, patchy-like transferlayer on the counterbody, which results from their ability to shear and delaminate under acting contact stress. Our study offers a framework for future investigations into utilizing MXene-based materials in tribological applications.

Keywords Plus:TRIBOLOGICAL PROPERTIES,MXENE TI3C2,MAX PHASES,TI3ALC2,MICROSTRUCTURE,SPECTROSCOPY,FRICTION

Published in CERAMICS INTERNATIONAL,Volume 50;10.1016/j.ceramint.2024.04.314,AUG 1 2024