Abstract

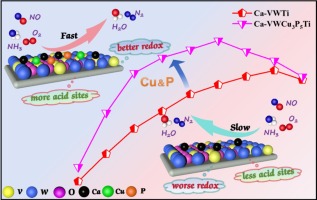

CaO was the inevitable cause of V2O5 -WO3 -TiO2 catalyst (VWTi) poisoning in cement kilns. The significant reduction in NO conversion was due to the combination of CaO and active species of the vanadium -based catalyst. In this work, the VWTi catalysts were modified with different contents of Cu and P to improve resistance to CaO, thereby extending the service life of catalysts in cement kilns. By doping Cu and P, the CaVWCu3P5 Ti had better catalytic activity, reduced the poisoning effect of CaO to V5+ , thus protecting the redox properties and increasing the surface acidic sites of the catalyst. Meanwhile, the in-situ DRIFTs results showed that the poisoning effect of CaO was weaker on the Ca-VWCu3P5 Ti than that of the Ca-VWTi. In addition, the NH3 and NO species could be effectively adsorbed and activated on the surface of the Ca-VWCu3P5 Ti by E -R mechanism. In this way, the harm of CaO to the vanadium -based catalysts was effectively reduced. This work provided a promising strategy to design vanadium -based catalysts with superior resistance to CaO in NH3 -SCR reaction.

Keywords Plus:ALKALI-METAL,SURFACE-ACIDITY,ACTIVE-SITES,NITRIC-OXIDE,REDUCTION,NO,V2O5-WO3/TIO2,NH3-SCR,RESISTANCE,NH3

Published in CHEMICAL ENGINEERING JOURNAL,Volume 492;10.1016/j.cej.2024.152382,JUL 15 2024