Abstract

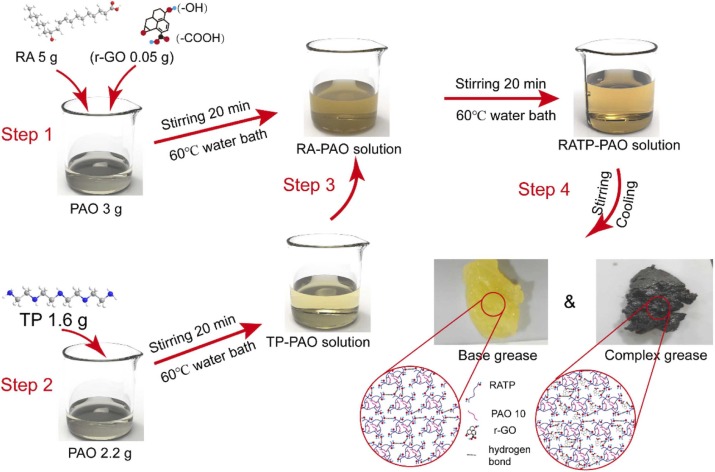

Load-carrying capacity and electrical stability are important factors in evaluating the performance of conductive grease. In this paper, a non-soap conductive grease is prepared to simultaneously enhance the wear resistance and conductivity of copper-copper friction pairs. Experimental results show that compared with AnRunt commercial grease, the COF of conductive grease with ricinoleic acid amide thickener is reduced by 43 %, the wear rate is reduced by 69 %, and the contact resistance decreases by 26 %. The introduced hydrogen bonds have a positive effect on friction reduction, anti-wear and conductivity. The conductive grease prepared in this paper provides a new perspective for the development of innovative conductive grease.

Keywords Plus:IONIC LIQUIDS,LUBRICANT ADDITIVES,MECHANISM,METAL

Published in TRIBOLOGY INTERNATIONAL,Volume 199;10.1016/j.triboint.2024.109958,NOV 2024