Abstract

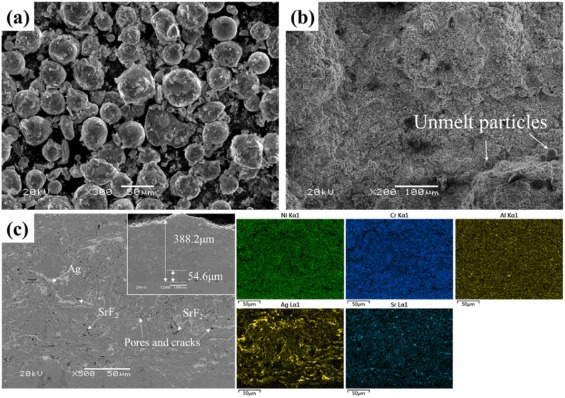

Self-lubricating coating is used to solve the problem of insufficient lubrication and failure of mechanical transmission parts at high temperature. In this work, we designed a NiCrAlY-Ag-SrF2 2 coating through the synergistic lubricating effect of a novel SrF2 2 lubricant and Ag, and the reinforcing action of in-situ formed oxides. The results showed that the NiCrAlY-Ag-10 wt% SrF2 2 coatings have high bond strength (60 MPa) and hardness due to the low porosity and production of in-situ oxides. From room temperature (RT) to 900 degrees C, the friction coefficient and wear rate of the coating are 0.29-0.47 and 1.03 x 10-5-5-6.74 x 10-5-5 mm3/N & sdot;m, 3 /N & sdot;m, respectively. This reveals that SrF2 2 can be employed as an alternative to high temperature lubricants, and the coatings achieve lubrication effect at a wide temperature range.

Keywords Plus:PLASMA,BEHAVIOR,COMPOSITES,OXIDATION,STRENGTH,AG

Published in TRIBOLOGY INTERNATIONAL,Volume 199;10.1016/j.triboint.2024.110047,NOV 2024