Abstract

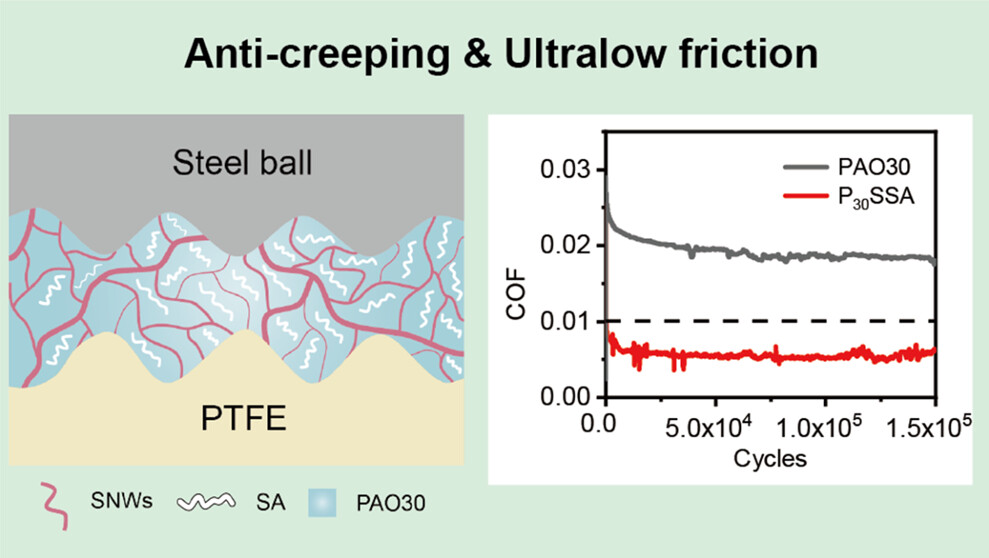

Liquid lubricants can reduce the friction and wear of two relative moving surfaces. However, there are still great challenges to achieve anticreep and superlubricity of liquid lubricants at the same time. In this study, a novel semisolid lubricant (P30SSA) was designed by fixing poly-alpha-olefins 30 (PAO30) base oil in a three-dimensional network structure constructed by subnanowires (SNW) and stearic acid (SA), avoiding the creep problem of base oil and achieving ultralow friction (0.006-0009) at steel/polytetrafluoroethylene (PTFE) interfaces in a short period (similar to 6 s). Compared with dry friction, the wear rate of the PTFE was reduced by 98%. Moreover, the friction coefficient remains below 0.01 after more than 150,000 cycles. The ultralow friction behavior is attributed to the increasing bearing ability caused by the three-dimensional network structure in P30SSA, the reduced internal friction of P30SSA generated by the shear thinning of the lubricant during the friction process, and the physisorption film formed on the surface of friction pairs. The P30SSA solves the problem of liquid lubricant creeping and achieves ultralow friction on the surface of steel/PTFE. This work opens up a new direction for semisolid lubricants and provides a new idea for the study of the ultralow friction mechanism.

Keywords Plus:GEL LUBRICANTS,SUPERLUBRICITY,NANOPARTICLES,MECHANISM,NITRIDE,WATER,NM

Published in CHEMSUSCHEM Volume 17;10.1002/cssc.202401224,DEC 20 2024