Abstract

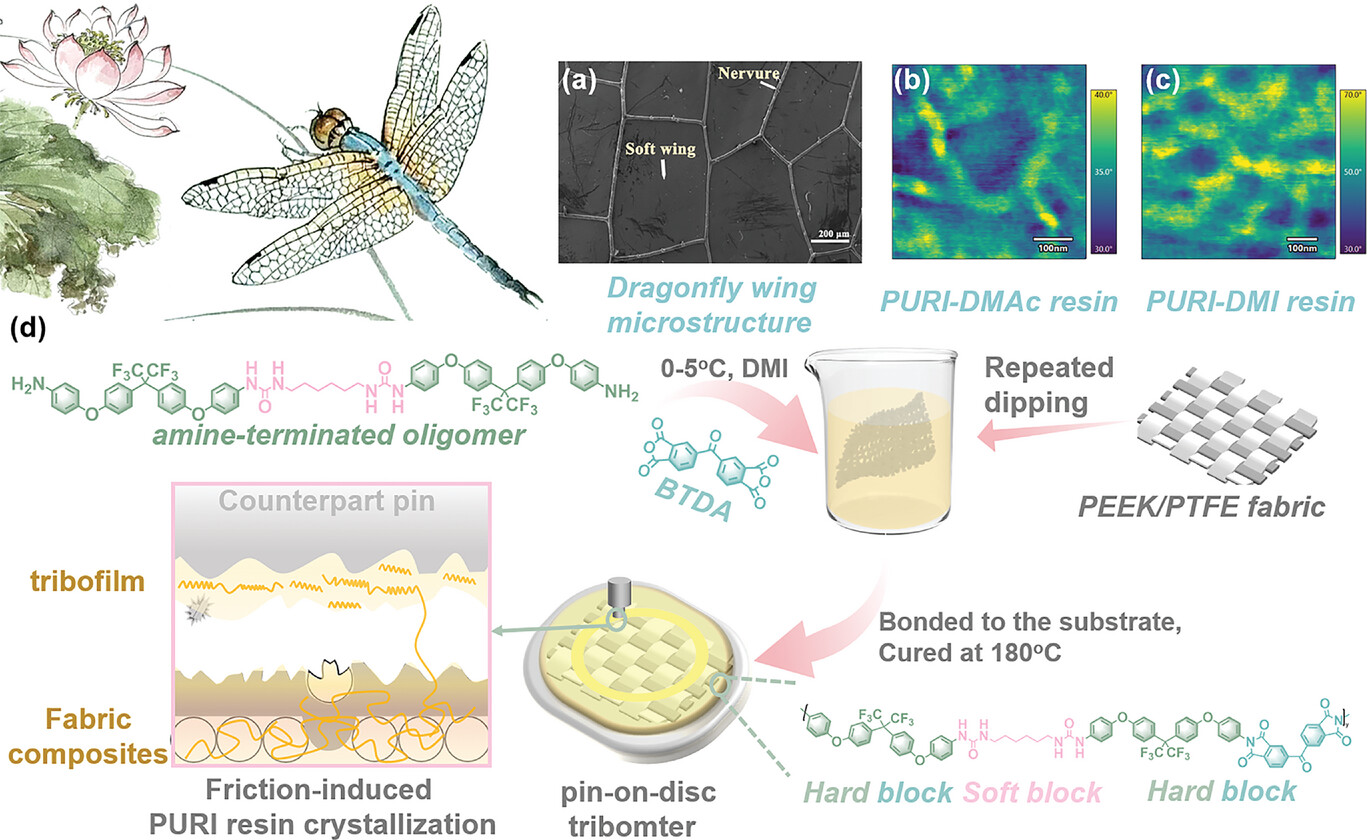

Polymer composite materials encounter considerable challenges in sustaining superior tribological properties at high rotational speeds. Inspired by the microstructure of dragonfly wings, a novel thermally stable and ambient pressure curing poly(urea-imide) resin (PURI) with excellent tribological properties has been eco-friendly synthesis using bio-based greener solvents. Furthermore, The PURI composites enhanced with polyether ether ketone (PEEK) and Polytetrafluoroethylene (PTFE) blended fabrics demonstrate excellent mechanical, with tensile strengths exceeding 175 MPa. The PURI composites synthesized in the green solvent dimethyl isosorbide (DMI) exhibit an average friction coefficient of 0.1160 and an average wear rate of 2.7 x 10-14 m3 (Nm)-1 at 800 r min-1. The excellent tribological performance is primarily attributed to the molecular chain rearrangement of the PURI resin during friction, which leads to the formation of crystalline structures in certain regions, a phenomenon known as friction-induced crystallization. This process is an entropy-reducing mechanism that absorbs other forms of energy, such as frictional heat, during the frictional process. Moreover, the PTFE fibers underwent tribochemical reactions resulting in changes to lattice spacing during friction and contributing to the formation of the tribofilm. This study provides new evidence regarding the frictional mechanisms of polymer composites, which is beneficial for designing high-performance wear-resistant composites.

Keywords Plus:WEAR BEHAVIOR

Published in SMALL;10.1002/smll.202408249