Abstract

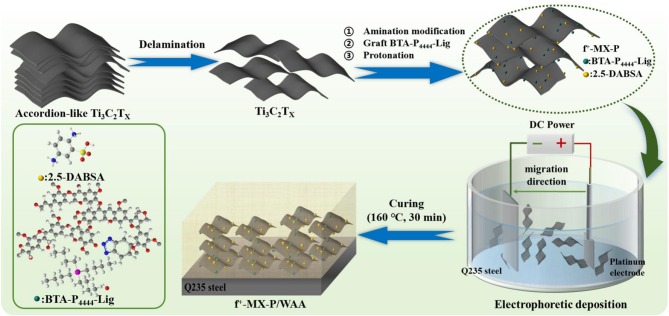

MXene's excellent corrosion resistance and self-lubricating properties allow it to be used as a filler in organic coatings to improve the protective properties of organic coatings. However, the random distribution of MXene (MX) in the coating can result in coating defects that make it impossible to meet higher protection requirements. To overcome this deficiency, this study builds upon previous research by employing a simple and environmentally friendly electrophoretic deposition technique. MX functionalised by ionic liquids (BTA-P4444-Lig) and protonated by HCl (f+-MX-P) is made to align in parallel in waterborne acrylic coatings (WAA) under the action of electric field force. This meets the higher protection requirements of organic coatings. Electrochemical tests show that the |Z|f=0.01 of f+-MX-P/WAA is 3 to 4 orders of magnitude greater than WAA. Parallel distribution of f+-MX-P in WAA is utilized to forma more continuous, uniform physical barrier and "inverse nacre effect", which greatly extends the diffusion pathway for corrosive medium. Meanwhile, XPS testing showed that BTA-P4444-Lig loaded on the f+-MX-P surface could form a adsorbed layer on the metal surface. The "inverse nacre effect" formed by MX in WAA and the synergistic effect of BTA-P4444-Lig enhanced the corrosion resistance of the f+-MXP/WAA. The outcomes of the friction testing indicate that the coefficient of friction for the f+-MX-P/WAA is lower at 0.103. This value is notably lower than that of WEP, which has a friction coefficient of 0.843. This is due to the fact that the parallel distribution of f+-MX in the coating has a certain inclination to the direction of crack propagation which effectively hinders crack propagation during friction. This reduces coating damage caused by crack propagation during friction, resulting in excellent wear resistance of f+- MX-P/WAA.

Keywords Plus:CORROSION PROTECTION,CARBON NANOTUBES,PERFORMANCE,COMPOSITES

Published in PROGRESS IN ORGANIC COATINGS,Volume 199;10.1016/j.porgcoat.2024.108948,FEB 2025