Abstract

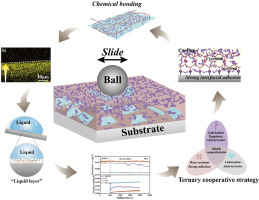

The surface of the friction pair needs to balance lubrication and corrosion resistance functions to ensure longterm durability in marine environment. Solid-liquid composite lubrication coatings combine the advantages of solid and liquid materials to exhibit excellent lubricating properties, enhanced wear resistance, increased service life. However, solving the coupling damage problem of wear and corrosion still faces challenge. This study addresses these challenges through ingeniously fabricating a novel solid-liquid composite coating with a gradient distribution of polydimethylsiloxane (PDMS) with extreme high content through cross-linked and entanglement with polysilazane and chemically bonded Mxene. It ensures strong interfacial adhesion and exhibits excellent lubricating performance with ultra low friction coefficient (COF approximate to 0.04), corrosion resistance (over 120 days of artificial seawater immersion), and negligible wear, even liquid PDMS content is as high as 120%. The composite coating exhibited minimal open circuit potential (OCP) fluctuation, indicating the most stable surface condition under tribo-corrosion in artificial seawater. In addition, compared to traditional solid-liquid composites, the novel chemically modified solid-liquid composite coating offers more effective protection for metal substrates while ensuring strong interfacial bonding. This work provides a novel and feasible approach for marine lubrication and anti-corrosion engineering applications.

Keywords Plus:AMINO-FUNCTIONALIZED TI3C2TX,STRATEGY

Published in CARBON,Volume234;10.1016/j.carbon.2024.119961,MAR 5 2025