Abstract

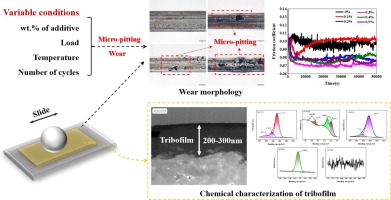

Micro-pitting is one of the common failure modes of mechanical components such as bearings and gears, and the generation of micro-pitting is closely related to the operating conditions. In this study, the effect of an ashless anti-wear additive, acidic dialkyl dithiophosphate (DDP-2) on micro-pitting was investigated using a TE77 high frequency friction machine. The micro-pitting on the worn surface was examined under different test conditions. The findings of the study indicated that the incorporation of DDP-2 resulted in a near 90 % reduction in wear in comparison to the base oil, with the majority of the coefficients of friction exhibiting a notable decline of approximately 20 %. As the concentration of DDP-2 increased, the surface wear diminished by approximately 10 %. However, concurrently, the surface micro-pitting augmented. There was a positive correlation between the number of contact cycles and micro-pitting at the same concentration. Furthermore, elevated temperatures result in a reduction in lubricant viscosity, which in turn leads to an increase in contact between surface roughness peaks, thereby exacerbating surface micro-pitting. An increase in load rate accelerates the rate of surface wear, which is in competition with micro-pitting. When the load exceeds 100 N, surface wear becomes the dominant phenomenon and effectively mitigates micro-pitting.

Keywords Plus:MICROPITTING PERFORMANCE,SPECTROSCOPY,ADDITIVES,ANTIWEAR,GROWTH,ESTER,GEARS,ZDDP

Published in APPLIED SURFACE SCIENCE,Volume688;10.1016/j.apsusc.2024.162220,APR 15 2025