Abstract

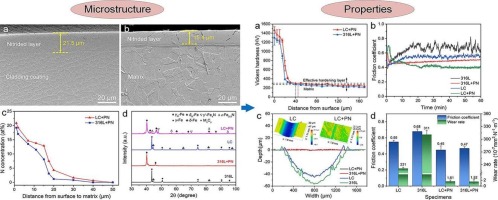

In order to improve the surface performance of laser cladding AISI 316L coating, low-temperature plasma nitriding (PN) was performed. The results indicated that the surface hardness and wear resistance of the nitrided cladding coating were significantly improved, accompanied by the transition of wear mechanism from abrasive wear and adhesive wear to oxidative wear and adhesive wear. The decrease in friction coefficient and wear rate could be ascribed to hard nitrided layer and the oxide layers created by friction. Comparing with traditional PN of 316L, high internal strain and dislocation density induced by laser cladding can improve PN efficiency, resulting in better wear resistance. This work provides a new insight into laser cladding combined with PN process for wear-resistant 316L coatings.

Published in MATERIALS LETTERS,Volume383;10.1016/j.matlet.2024.137951,MAR 15 2025