Abstract

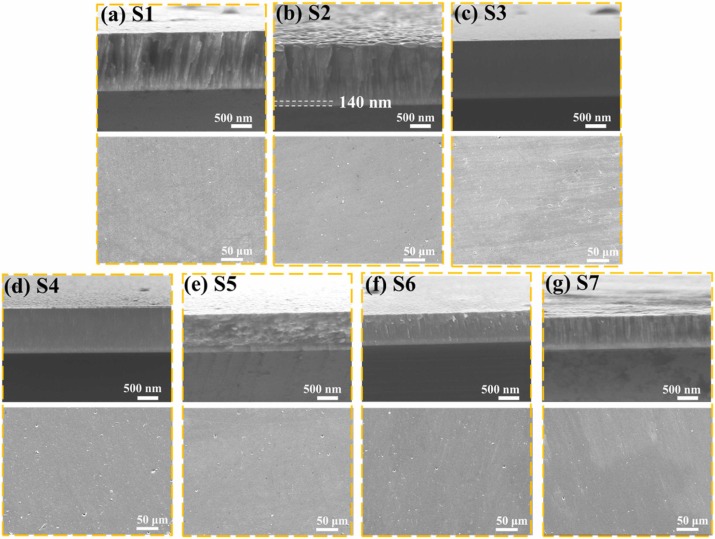

The (CrAlVTiNb)1-xNx films (x = 0-0.55) are deposited using high power impulse magnetron sputtering (HiPIMS), with variations in N2 flow rate influencing their microstructure, chemical composition, mechanical properties, and tribological behavior. Notably, as the N2 flow rate increases from 0 to 30 sccm, the film undergoes a transformation in morphology from columnar to dense and featureless, before reverting to columnar again, with the hardness initially rising from 12 to 30 GPa and then decreasing to 25 GPa. Films deposited at optimal N2 flow rates (15-25 sccm) exhibit excellent adhesion (LC3 critical loads of 45-52 N), with superior wear resistance achieved at 20 sccm. Additionally, the study reveals a unique interaction between tribo-oxidation wear and abrasive/adhesive wear, which varies across films with different densities. This research provides valuable insights into the relationship between process parameters and film properties, offering a novel approach for tailoring film characteristics to meet specific application demands.

Keywords Plus:MECHANICAL-PROPERTIES,THIN-FILMS,COATINGS,DEPENDENCE

Published in JOURNAL OF ALLOYS AND COMPOUNDS,Volume1020;10.1016/j.jallcom.2025.179395,MAR 15 2025