Abstract

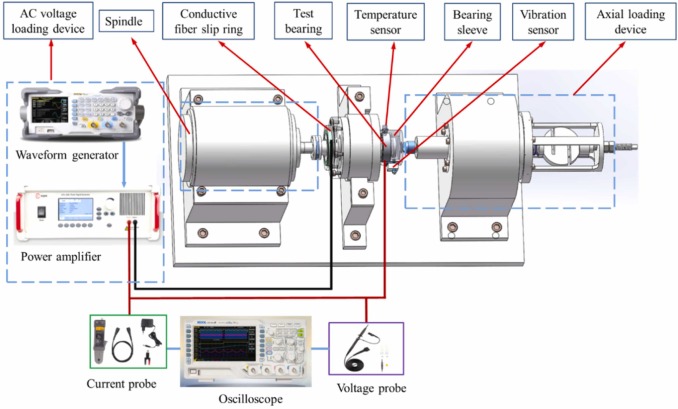

An electro-corrosion test rig for rolling bearings has been developed to investigate the effects of voltage amplitude, electric frequency, rotating speed, and axial load on the bearing fluting under alternating current (AC) fields. The results show that with an increase in the voltage amplitude, electric frequency, and rotating speed, the fluting damage stripes on the inner ring of the bearing first increase and then decrease. With an increase in axial load, the number of fluting stripes decreases. These trends of variation were discussed through parameters such as discharge activity frequency, current density, and lubrication status for different working conditions. Finally, for the relieve of fluting, after replacing one or three steel balls with ceramic ones, the transverse fluting stripes disappeared.

Keywords Plus:FILM THICKNESS,CURRENTS,SURFACE,MECHANISM,FAILURES,VOLTAGE

Published in TRIBOLOGY INTERNATIONAL,Volume208;10.1016/j.triboint.2025.110658,AUG 2025