Abstract

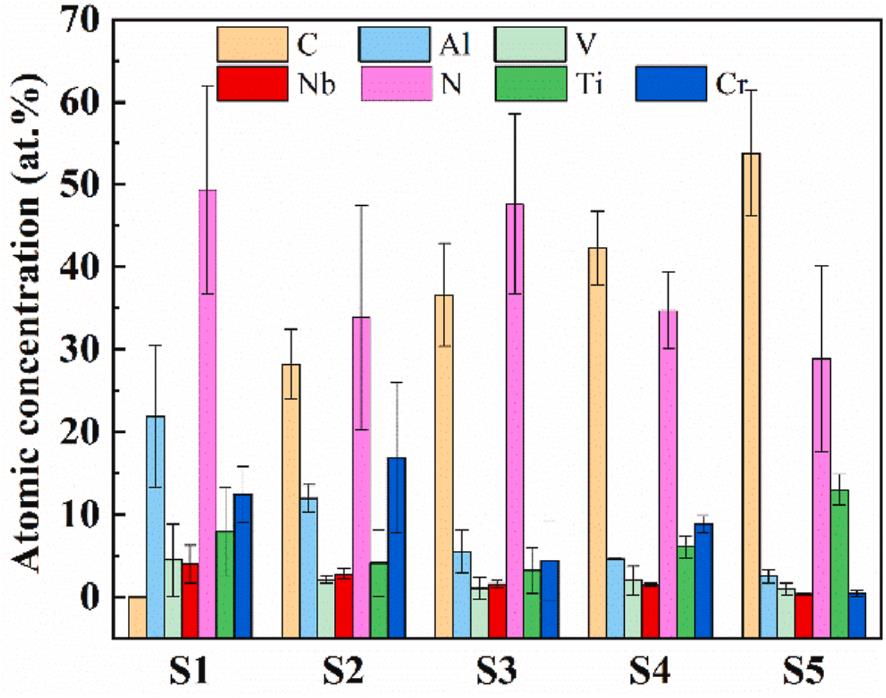

In this study, the (CrAlVTiNb)CxNx high-entropy carbonitrides coatings are fabricated by high power impulse magnetron sputtering. Variation in the morphology, phase structure, mechanical properties and tribological performance of the coatings as influenced by the carbon content are explored. The coatings undergo significant phase transformations with increasing carbon content, transitioning from an orthorhombic structure to a FCC structure, then to an amorphous phase, and finally to a HCP structure. The coating achieves maximum hardness and elastic modulus of approximately 32.6 GPa and 310.4 GPa, respectively, but excess amorphous carbon can relieve compressive residual stress, resulting decreased hardness and elastic modulus. The tribological evaluation reveals that the S5 coating exhibits the lowest average friction coefficient (similar to 0.2), while the S2 coating shows the lowest wear rate of about 1.44 x 10(-6) mm(3) N-1 m(-1). However, excessive introduction of carbon can reduce the wear resistance of the coating and make it more susceptible to oxidative wear. The findings enhance the fundamental understanding of coating formation processes and pave the way for innovative material design strategies, enabling the development of high-performance coatings that can adapt to evolving technological needs.

Keywords Plus:MULTIELEMENT,FILMS,DLC

Published in CERAMICS INTERNATIONAL,Volume51;10.1016/j.ceramint.2025.01.186,APR 2025