Abstract

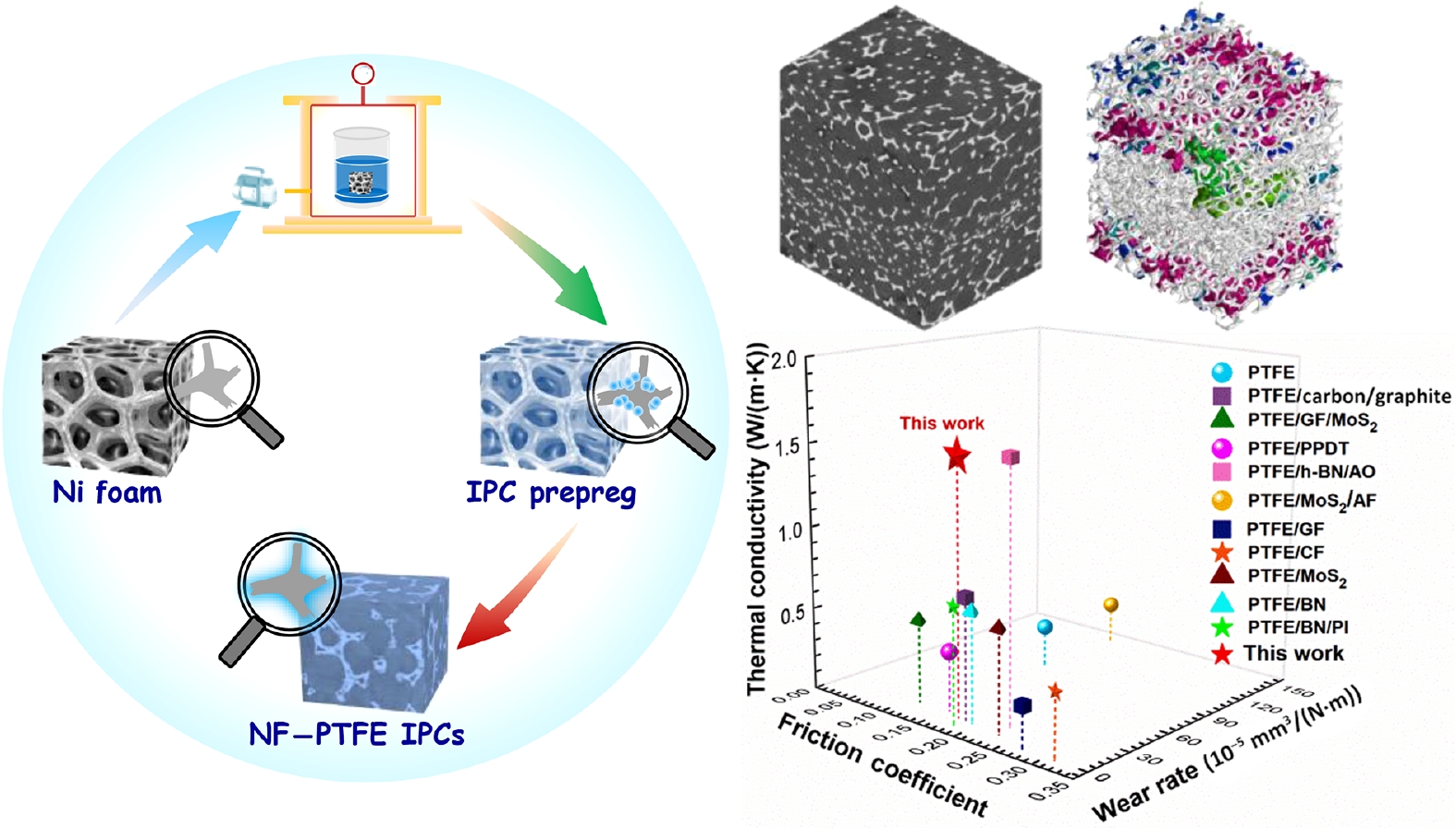

Nickel foam (NF)-polytetrafluoroethylene (PTFE) interpenetrating phase composites (IPCs) were prepared via vacuum-assisted emulsion impregnation and free sintering. The effects of the pores per inch (PPI) of the NFs on the microstructure, mechanical properties, thermal conductivity, and tribological properties were investigated. The results indicated that the incorporation of a three-dimensional Ni skeleton inhibited heat accumulation at the friction interface, and the thermal conductivity and wear resistance of the composite significantly improved with increasing PPI. Compared with those of the PTFE matrix, the thermal conductivity of the 80 PPI NF-PTFE IPCs improved by '394% and the wear rate decreased by up to '66%.

Keywords Plus:HIGH THERMAL-CONDUCTIVITY,PHASE COMPOSITES,PTFE COMPOSITES,WEAR BEHAVIOR,POLYMERS,FOAM

Published in FRICTION,Volume13;10.26599/FRICT.2025.9440948,MAY 2025