Abstract

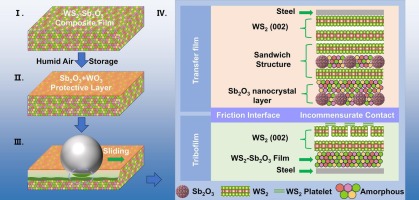

Solid lubrication films of transition metal dichalcogenides (TMDs) often suffer from degraded tribological performance after exposure to humid environments, severely limiting their aerospace applications. This study systematically investigated the structural evolution and tribological behavior of magnetron-sputtered WS2-Sb2O3 composite films before and after 120-hour humid air storage. The analysis results revealed that Sb2O3 was partially reduced to Sb by Ar ion bombardment during film deposition, resulting in the coexistence of Sb2O3 and Sb in the composite films. Metallic Sb exposed on the composite film surface was oxidized to Sb2O3 in humid air, which combined with WO3 to form a protective barrier. The stored composite films with suitable Sb2O3 content maintained an ultra-low friction coefficient (similar to 0.01) and a minimal wear rate (similar to 8 x 10(-8) mm(3).N-1.m(-1)) even after humid storage. Crucially, cross-sectional TEM analysis revealed Sb2O3 nanocrystals accumulated on the transfer film surface of the composite film, with a portion of these nanocrystals forming a sandwich-like structure. The presence of these nanocrystals in the transfer film significantly reduced the friction coefficient of the composite films.

Keywords Plus:SPUTTERED MOS2 FILMS,TRIBOLOGICAL PROPERTIES,NANOCOMPOSITE COATINGS,COMPOSITE COATINGS,ION BATTERIES,OXYGEN,WEAR,SUPERLUBRICITY,LUBRICATION,ORIENTATION

Published in APPLIED SURFACE SCIENCE,Volume704;10.1016/j.apsusc.2025.163440,SEP 30 2025