Abstract

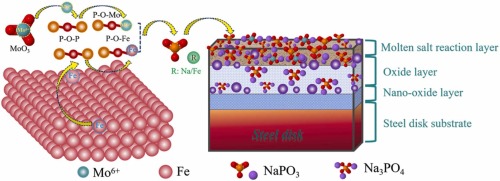

The development of high temperature rolling lubricants is critical for reducing frictional wear/oxidation, enhancing surface quality, and decreasing energy consumption in steel processing. This study proposes a tribochemical design strategy for boundary/mixed lubrication systems based on molten salt reactions at hot rolling interfaces. Six composite aqueous lubricants containing sodium polyphosphate (DP) blended with sodium molybdate dihydrate, sodium carbonate, sodium silicate, sodium borate, or their combinations (3.75:1 wt ratio) were systematically investigated. Tribological evaluation revealed that all composite lubricants significantly outperform pure DP solutions, with the DP/sodium molybdate system demonstrating exceptional performance: 49.2 % reduction in friction coefficient and 95.6 % decrease in specific wear rate under laboratory testing. Industrial-scale hot rolling trials (1150 degrees C, 40 % reduction ratio) confirmed its superior performance, achieving 64.6 % reduction in surface roughness and maintaining oxide layer thickness below 30 mu m. Advanced characterization revealed the outstanding lubrication originates from the synergistic formation of a molten tribo-film containing Na3PO4, NaPO3, and Na2MoO4 phases, coupled with shear-induced nano-structured iron oxide interlayers at the steel interface. This work establishes a fundamental framework for designing wide-temperature (500-1200 degrees C) composite alkali salt lubricants through controlled tribo-chemical reactions, providing critical insights for industrial metal-forming applications.

Keywords Plus:TRIBOLOGICAL PROPERTIES,WEAR PERFORMANCES,FRICTION,BORATE,STEEL,BEHAVIOR,GLASSES,COMPOSITE,MOLYBDATE,SILICATE

Published in TRIBOLOGY INTERNATIONAL,Volume211;10.1016/j.triboint.2025.110925,NOV 2025