Abstract

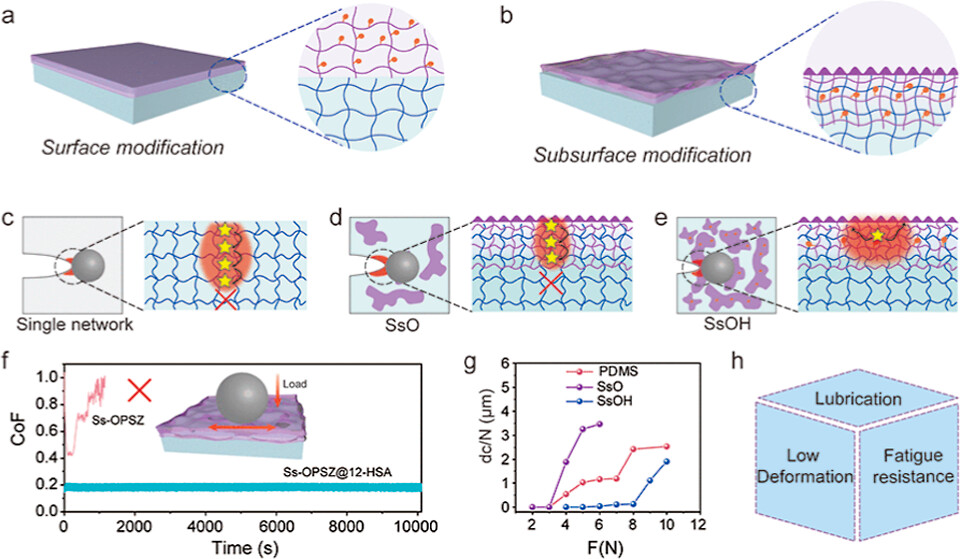

Lubricating coatings with excellent fatigue resistance on inert rubber surfaces significantly reduce friction and wear, thereby extending the material durability and lifetime. Conventional coating strategies often face challenges in simultaneously achieving robust interfacial adhesion and low viscosity hysteresis during dynamic sliding. Herein, we propose a solvent-mediated semi-interpenetrating polymer network approach to construct subsurface-embedded lubricating structures. By utilizing solvent-swelling-assisted permeation of a lubricant-modified rigid polysiloxane into rubber matrices, followed by in situ alcoholysis and curing, a hard yet flexible semi-interpenetrating network (semi-IPN) hybrid layer is synthesized. This surface network structure reduced adhesion and hysteresis during the friction test, exhibiting an excellent lubrication effect under 10,000 wear cycles. While the entanglement endowed the coating with excellent fatigue resistance with a low extension rate and a threshold of 7 N compared to the bare polydimethylsiloxane (PDMS) of 3 N. By selectively modifying polysiloxane, other properties, such as oil repellency, can be imparted to the coating surface. Adaptable to polymer modification by using suitable solvents, this method provides an efficient solution for creating durable, lubricating surfaces, broadening its potential applications in multiple industries.

Keywords Plus:TRIBOLOGICAL PROPERTIES,VISCOELASTICITY,LUBRICATION,FRICTION,BEHAVIOR

Published in ACS APPLIED MATERIALS & INTERFACES,Volume17;10.1021/acsami.5c09180,AUG 6 2025