Abstract

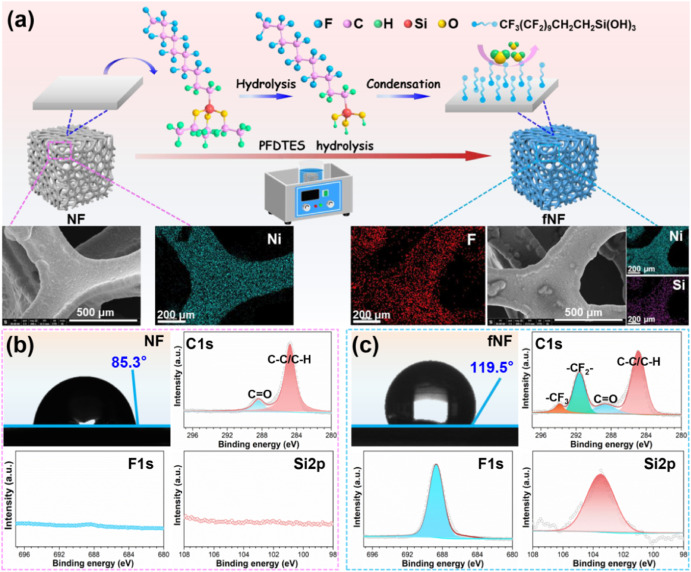

Interpenetrating phase composites (IPCs) composed of metal and polymer have received extensive attention because of their hybrid structure and multiple properties, which are largely influenced by the 3D heterogeneous metal-polymer interface and bonding strength with functional fillers dispersed in the polymer matrix. Herein, a dual modification of reticulate nickel foam (NF) skeleton via fluorosilane and continuous PTFE matrix by compositing fluorinated graphite (FGr) microsheets is reported. NF-PTFE IPCs with enhanced 2D and 3D interfaces reveal multi-dimensional increases in thermal transfer efficiency, mechanical strength and wear resistance. Compared with that of the PTFE matrix, the thermal conductivity of the developed IPC increases by up to similar to 299 %. The further incorporation of FGr helps decrease the wear rate by similar to 90.7 %, owing to the enhanced load transfer, strain distribution at the interfaces and transfer film formation composed of multiple components. This dual-modification strategy effectively enhances the performance of metal-polymer IPCs by promoting load and heat transfer at internal 2D-3D interfaces and friction transfer at the friction interface.

Keywords Plus:TRIBOLOGICAL BEHAVIOR

Published in COMPOSITES PART B-ENGINEERING,Volume306;10.1016/j.compositesb.2025.112816,NOV 1 2025