Abstract

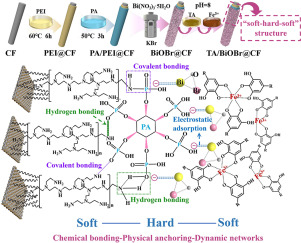

This paper reports a method of bionic constructing of a "soft-hard-soft" multi-stage structure as a transition layer at the interface of carbon fiber and polytetrafluoroethylene fiber blended fabric (CF/PTFE fabric) self-lubricating composites, which can significantly improve the anti-friction and wear resistance, thermal stability and interfacial adhesion of the composites. The friction tests showed that the CF/PTFE fabric composites with interface enhancement exhibited excellent self-lubricating performance under different loads and linear speeds, in which the wear rate and the coefficient of friction were reduced by approximately 65 % and 36 %, respectively, compared with pure CF/PTFE composites. Moreover, FIB-TEM results indicated that the tribofilm presented a unique dual-layer structure. In addition, thermogravimetric analysis and peel tests showed that the interfacial reinforced CF/PTFE fabric composites had higher thermal stability and interfacial bonding strength, with a residual mass at 800 degrees C that was 23.8 % higher than that of pure CF/PTFE composites. The interfacial peel strength was increased by 53.3 %. This study, through multi-level functional design, not only significantly improved the tribological properties of CF/PTFE fabric composites, but also provided a new idea for their application in hightemperature and high-speed friction environments.

Keywords Plus:CARBON FIBER/EPOXY COMPOSITES,REINFORCED EPOXY COMPOSITES,MECHANICAL-PROPERTIES,FRICTION

Published in COMPOSITES PART B-ENGINEERING,Volume307;10.1016/j.compositesb.2025.112856,NOV 15 2025