Abstract

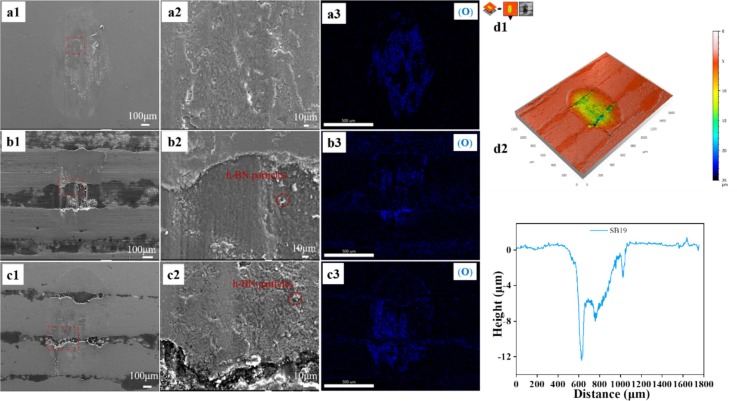

In this study, the frictional characteristics of Si3N4-BN layered ceramic materials were examined by tailoring the mass ratio of the matrix to interface layers and the sintering temperature, mimicking the nacreous structure. The layered ceramics prepared exhibited an 8.5 % reduction in friction coefficient (0.54) and a 68.9 % decrease in wear rate (0.952 x 10-6 mm3/N & sdot;m) compared to non-layered ceramics. The excellent frictional performance of layered ceramics stems from the inclusion of a lubricating h-BN layer, which effectively mitigates friction during sliding. Moreover, the SiO2 oxide film formed during friction further mitigates wear. Consequently, these tribologically superior layered ceramics hold promise for broadening the application scope of Si3N4 ceramic materials.

Published in MATERIALS LETTERS,Volume402;10.1016/j.matlet.2025.139203,JAN 1 2026