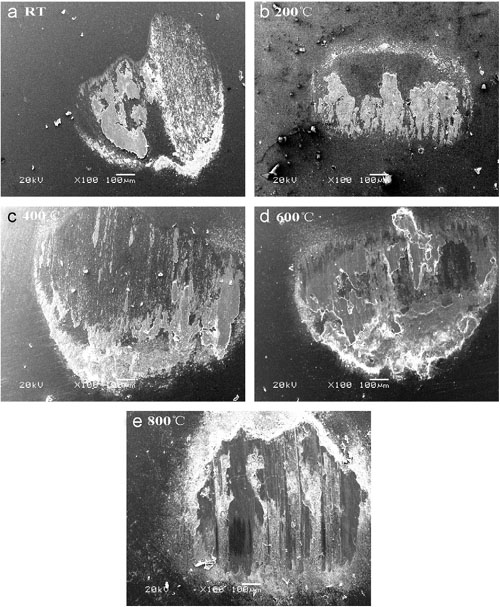

Worn surfaces of the coupled balls of NFAC (Ni3Al–6.2BaF2–3.8CaF2–12.5Ag–10Cr) at different temperatures.

Researchers of the Lanzhou Institute of Chemical Physics of the CAS have fabricated a Ni3Al matrix high temperature self-lubricating composite Ni3Al–BaF2–CaF2–Ag–Cr by the powder metallurgy technique and investigated tribological behavior at a wide temperature range from room temperature to 800℃.

The results indicated that the composite exhibited low friction coefficients (0.30–0.36)and wear rates(0.65–2.45×10-4 mm3 N-1 m-1). It was found that the low friction coefficient was attributed to the synergistic effects of Ag, fluorides and chromates formed in the tribo-chemical reaction at high temperatures. The low wear rate of the composite was due to the high strength and the excellent lubricating properties.

In the past years, Ni3Al intermetallic materials have been extensively investigated due to their potential for high temperature applications. A great deal of work has been addressed to the study of the effect of alloying elements, mechanical properties, oxidation and corrosion. The results indicated that Ni3Al may be an excellent matrix for a high temperature self-lubricating composite owing to its high temperature strength, good oxidation resistance and corrosion resistance behavior. To the authors’ knowledge, till now, the tribological behavior of Ni3Al matrix composite has not been researched systemically.

The work has been supported by the Innovation Group Foundation of the National Natural Science Foundation of China and National Program on Key Basic Research Project of China. The findings have been published in Tribology International (Tribology International 44 (2011) 445–453).