Ocean exploitation requires specialized equipment, which must be adapted to the ocean environment. Similar to land-based equipment, ocean-based equipment also needs friction components. Therefore, it is very important to investigate the tribological properties of materials under the ocean environment.

Presently, materials used in the ocean environment are mainly metals and their alloys. Compared to traditional metal materials, polymers have some excellent properties, such as low density, high insulation to heat and electricity, good fatigue resistance, self-lubrication, excellent corrosion resistance, and the ability of embedding foreign particles. Therefore, polymer materials are very promising and suitable materials for frictional application in the ocean environment.

Researchers from the State Key Laboratory of Solid Lubrication of the Lanzhou Institute of Chemical Physics of the CAS have investigated the tribological behaviors of polyether ether ketone (PEEK), poly(phenyl p-hydroxybenzoate) (PHBA), polyimide (PI), and perfluoroethylene propylene copolymer (FEP) sliding against GCr15 and 316 steel rings under the lubrication of sea water and compared with that under the lubrication of pure water.

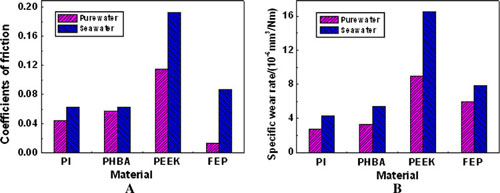

The results show that the friction and wear behaviors of a polymer under the lubrication of aqueous mediumare not only related to the properties of polymer itself, but also to the corrosive effect and lubricating effect of the medium. When a polymer slid against GCr15 steel under sea water lubrication, the friction coefficient and wear rate of polymer were much larger than that under pure water lubrication because of indirect corrosive wear. However, when sliding against corrosion resistant 316 steel, polymers PEEK, FEP, and PI exhibited lower coefficients of friction and wear rates under sea water lubrication, this was attributed to better lubricating effect of sea water as a result of the deposition of CaCO3 and Mg(OH)2 on the counterface. On the contrary, the friction coefficient and wear rate of PHBA sliding against 316 steel under sea water lubrication were larger than that under pure water lubrication, which may be related to the properties of PHBA itself.

The work has received support from the National Natural Science Foundation of China and the National High-Tech Research and Development Program of China.

The detailed report has been published in Tribol Lett (Tribol Lett (2011) 42:17–25).

Friction coefficients and specific wear rates of four polymers materials sliding against GCr15 under pure water and sea water lubrication

Friction coefficients and specific wear rates of four polymers sliding against 316 steel under pure water and sea water lubrication