HfB2, a type of ultra-high-temperature ceramics (UHTCs), has attracted muchattention due to its excellent and unique combination of high hardness, high melting point (3000℃), high electrical and thermal conductivity, resistance to erosion/corrosion, good thermal shock resistance, low coefficient of thermal expansion, retention of strength at elevated temperatures, and stability in extreme environments. However, there have been few articles describing the HfB2-reinforced Ni-based MMC coatings.

Researchers at the R&D Center of Lubricating and Protecting Materials of the Lanzhou Institute of Chemical Physics have systematically investigated the effect of HfB2-phase on the microstructure and tribological properties of the Ni-based metal matrix composite (MMC) coatings.

The results show that wear resistance of the pure Ti substrate and NiCrBSi coating greatly increased after laser cladding of the HfB2-containing composite coating due to the formation of hard phases in the composite coating. The pure Ti substrate sliding against the AISI-52100 counterpart ball at room temperature displayed predominantly adhesive wear, abrasive wear, and severe plastic deformation, while the HfB2-containing composite coating showed only mild abrasive wear and adhesive wear under the same conditions.

It is anticipated that the fabricated HfB2-containing composite coatings with excellent wear-resistance could act as candidate material for protective coatings.

The work has been financially supported by the National High-tech R&D Program of China (863 Program) nd the West Light Foundation of The Chinese Academy of Sciences.

The findings have been published in Tribol Lett (2011) 44:187–200).

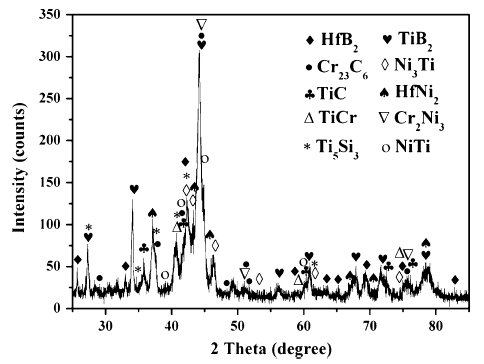

X-ray diffraction (XRD) patterns of the HfB2-containing composite coating