Researchers from the State Key Laboratory of Solid Lubrication of the Lanzhou Institute of Chemical Physics have synthesized a new kind of lubricating grease with a relatively high dropping point based on surface-modified attapulgite clay. The addition of additives MoS2 and the graphite/MoS2 mixture to the new lubricating grease resulted in the new lubricating grease having a better friction-reducing ability. As additive, the KB3O5 showed a relatively better anti-wear ability. Moreover, the additives of MoS2 and the graphite/MoS2 mixture were able to increase the load-carrying capacity of the new grease. XPS analyses indicated that tribofilms consisting of MoS2 and MoO3 compounds were formed on the worn surface under the grease containing MoS2, resulting in better tribological performance. Also, compared to the traditional bentone grease containing 5.0 wt% MoS2, the attapulgite clay grease containing MoS2 showed a better friction-reducing ability.

Many researchers have recently focused on a kind of new non-metallic mineral material, attapulgite clay. Attapulgite clay has many special surface and interface properties to attapulgite clay, including a larger specific surface area, surface activity, porous and adsorption ability, ion exchange, and salt resistance. There are reports of attapulgite being used in rubbers, adhesives, thermoplastic polymers, silicate/epoxy nanocomposite, catalyst supports, and environmental absorbents, etc. Attapulgite clay has a structure similar to that of bentonite. However, to date, there have been no reports on the use of organically modified attapulgite to synthesize lubricating grease.

The detailed report has been published in Tribol Lett (Tribol Lett (2011) 42:141–148).

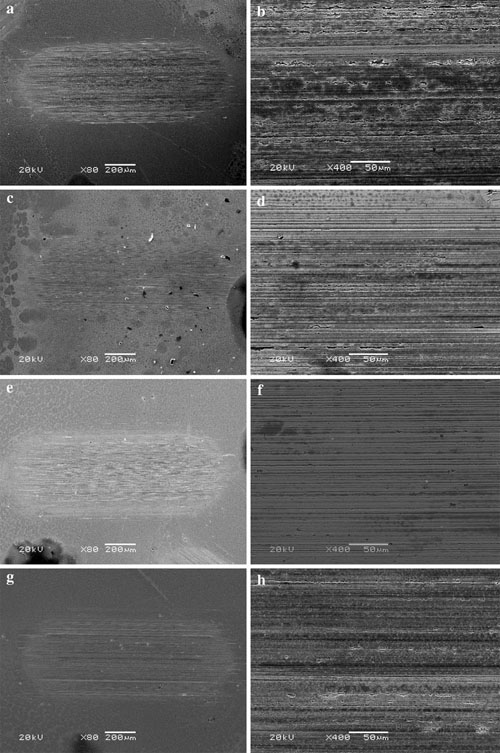

Scanning electron microscopy images of the morphologies of the wear surface lubricated with the different types of grease: a, b base grease, c, d grease containing KB3O5, e, f grease containing MoS2, g, h grease containing the graphite/MoS2 mixture (load 200 N, frequency 30 Hz)